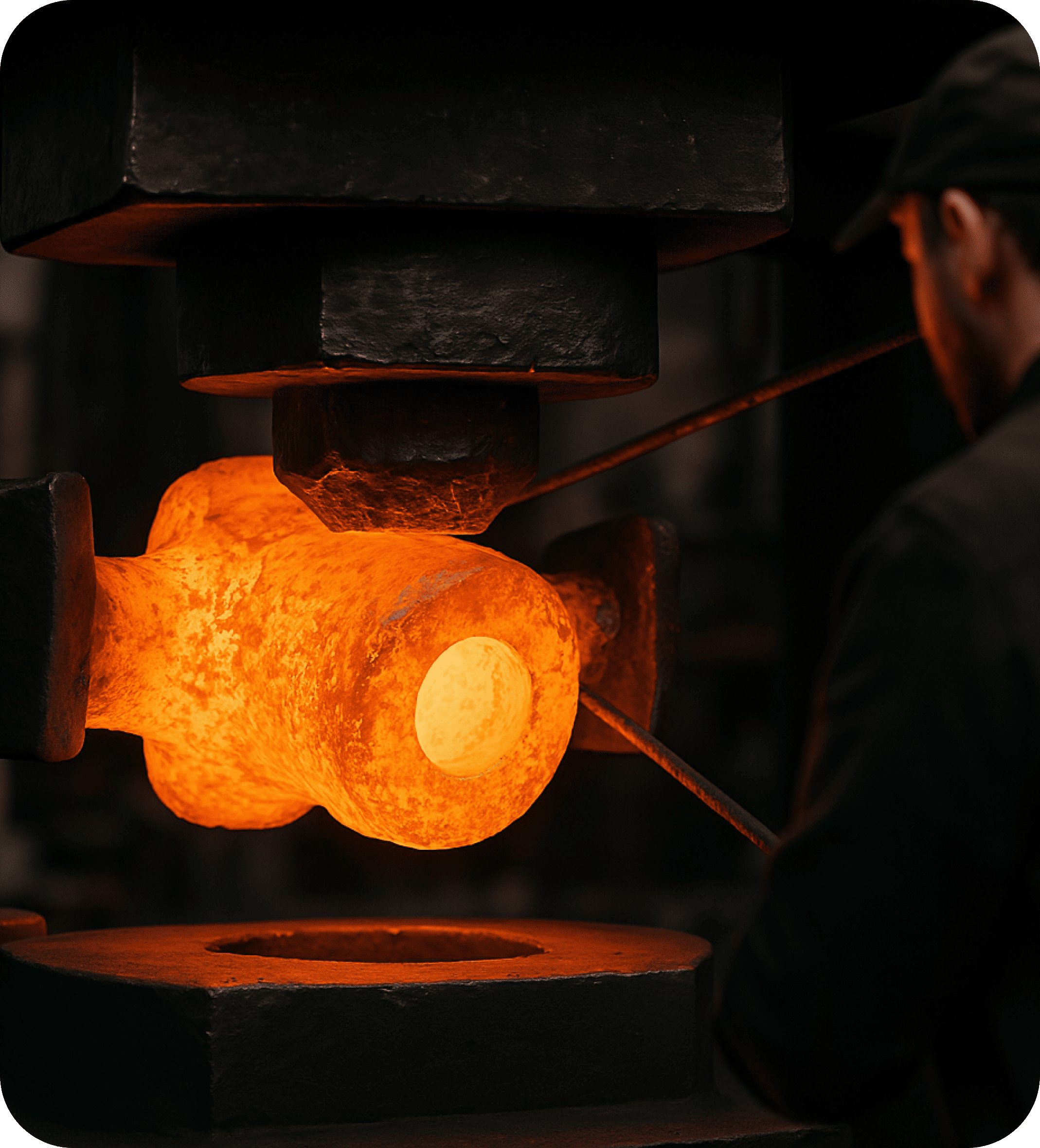

Forging

Discover how Tset enables precise costing for forging processes — from billet and die inputs to forming forces and press parameters. This demo highlights how users can simulate cycle times, calculate costs, and benchmark alternatives automatically within the forging module.

Hinweis: Das Video ist auf Englisch.

In Tset’s product costing software, the forging module automates bottom-up calculations for various forging technologies, including die forging and cold forging. This video demonstrates how users can model forging operations by inputting part geometry, material type, press configuration, and cycle parameters - enabling fast, precise simulations.

By integrating forging into your digital costing workflow, Tset helps procurement and engineering teams create reliable should-cost estimates, respond faster to RFQs, and negotiate supplier quotes based on transparent, data-driven calculations. The result? Improved cost control, quicker decisions, and less friction between design, procurement, and suppliers.

Explore our other calculation modules

High Pressure Die Casting

Generate detailed cost breakdowns and scope 3 upstream CO₂ data for high pressure die casting processes using Tset's automated module.

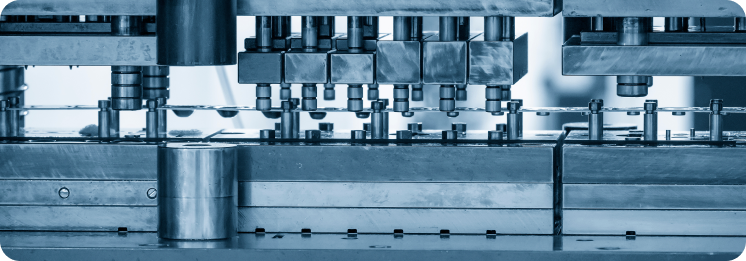

Transfer Die Stamping

Streamline transfer die stamping simulations to generate cost transparency and variant-specific calculations with minimal manual input.

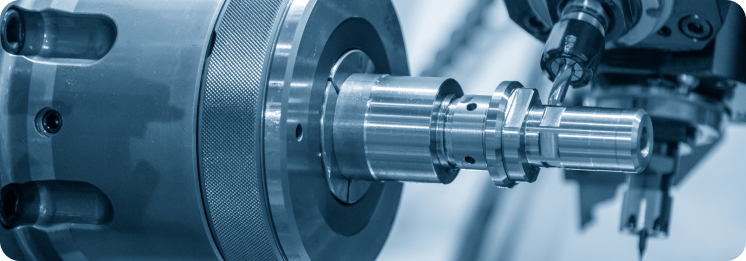

Machining

Tset's machining module enables fast, bottom-up cost analysis for turning, milling, grinding, and other machining operations with high accuracy.

See what makes your cost structure transparent.

Book a demo today to understand how structured cost models help your team make better decisions, faster.