The Problem with Assumptions: How to Bring Consistency into Your Should Cost Analysis

A part that costs €41 today might show up as €58 tomorrow - all depending on who ran the calculation. In manufacturing, where decisions about sourcing, design, and pricing hinge on accurate costing, relying on manual assumptions can erode trust and waste negotiation potential. And as products get more complex and customers demand product costs transparency, these inconsistencies become critical risks.

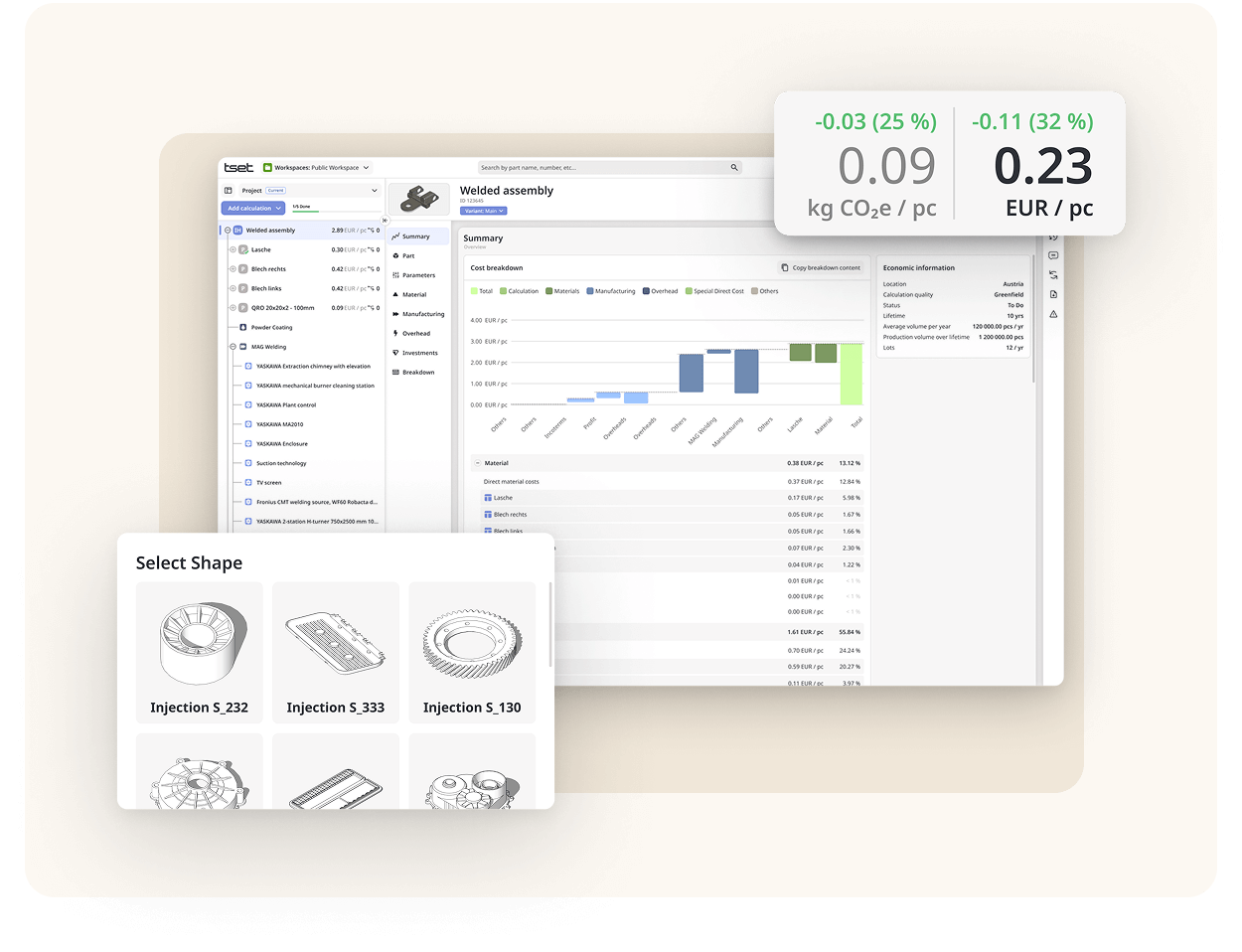

Today’s procurement and cost engineering teams are under pressure to deliver faster, clearer, and more consistent answers. This article explores the root cause: inconsistent assumptions in should cost analysis. We will break down what that really means, why it’s happening, and how modern costing platforms like Tset help replace guesswork with confidence.

What Is Should Cost Analysis and Where Do Assumptions Sneak In?

Should cost analysis is the process of estimating what a part or product should cost to manufacture based on materials, labor, machines, overhead, and other factors. It’s used to evaluate supplier quotes, support make-or-buy decisions, and guide product design.

But here’s the problem: in many companies, the inputs to those calculations, like cycle times, setup costs, labor rates, or material yields, aren’t standardized. They vary by user, by spreadsheet, by project. So even when the methodology is technically correct, the outcomes aren’t consistent. One engineer might assume a 3-minute cycle time. Another says 2.4. Multiply that across dozens of parts and suppliers, and the entire costing logic starts to unravel.

Why Now? Supply Chain Complexity and Cost Pressure Are Accelerating

Manufacturers across Europe are feeling the pressure of inflation, energy costs, and ongoing supply chain instability. In Germany alone, the ifo Institute reported a steady increase in manufacturers’ price expectations, with industrial companies continuing to plan price hikes throughout late 2024 and into 2025. Energy-intensive sectors in particular are facing steeper cost increases, affecting both direct and purchased part pricing.

Despite this complexity, many companies still rely on outdated tools to perform cost analysis. These tools were never built for version control, collaboration, or standardization, therefore leaving teams to make critical decisions based on inconsistent assumptions.

Inconsistent Assumptions and Isolated Tools

Across manufacturing - from automotive to machinery and components - teams face common challenges when it comes to costing:

-

Non-standard assumptions: Different users apply their own logic to estimate labor time, tool wear, material losses, or machine rates.

-

Excel-based workflows: Costing is buried in error-prone, unscalable spreadsheets.

-

Knowledge silos: Only a handful of people understand the logic behind each cost model.

-

Outdated software: Legacy systems require manual updates and maintenance, leading to skipped updates and inconsistent data.

This fragmentation leads to slow RFQ cycles, conflicting results, difficult supplier conversations, and poor onboarding for new team members.

How Tset Fixes the Assumption Problem

Tset is a cloud-based product cost software that brings consistency, speed, and traceability to should cost analysis without sacrificing flexibility or expertise.

1. Centralized, Always Up-to-Date Master Data

Tset replaces manually maintained Excel files with a rich, validated database, updated continuously:

-

11,600+ material prices across regions and alloys

-

769 region-specific labor, energy, and overhead factors

-

3,000+ machines with full cost logic

-

220+ manufacturing process templates

Your team always works with the same version of the truth - no manual uploads required.

2. Automated Cost Models with Custom Logic

Whether starting from a 3D file, BOM, or manual input, Tset’s cost modules run bottom-up calculations in seconds. Every assumption - cycle times, tool life, labor hours - is editable, so experts stay in control while enabling structure for everyone else.

3. Fast, Transparent CO₂ and Cost Breakdown in Every Estimate

Tset includes monetary and CO₂ output by default, with OEM-compliant export formats. Whether you’re comparing suppliers or responding to customer RFQs, results are traceable and complete.

4. Seamless Collaboration Across Teams

Tset enables global collaboration with real-time editing, version history, and role-based access. Your engineers, purchasers, and sales colleagues can work from the same shared logic - no file versions, no duplicate work, no lost knowledge.

5. Zero Maintenance Cloud Platform

No more skipped upgrades or admin work. Tset runs fully in the cloud with automatic updates, meaning your team always has access to the latest features and data, without IT overhead.

Want to see how others fixed their should cost analysis?

Read the case study to learn how manufacturers are cutting costs and gaining negotiation leverage with Tset.

From Guesswork to Confidence

By switching to Tset, manufacturing companies can:

-

Eliminate assumption-driven inconsistencies

-

Shorten RFQ response times with faster, automated estimates

-

Improve negotiation outcomes with standardized supplier cost breakdowns

-

Support sourcing and design decisions with real, comparable data

-

Meet CO₂ and transparency requirements with every calculation

Conclusion

If inconsistent assumptions are slowing you down, hurting your margins, or undermining supplier trust, it’s time to rethink how your team works. Tset helps you replace scattered spreadsheets and legacy tools with a connected, flexible, and scalable costing foundation.

Ready to Bring Clarity to Your Should Costing?

Book a demo today and see how Tset brings structure, speed, and confidence to your cost analysis.