Speed Up Machinery Costing Without Sacrificing Accuracy

Simulate cost and CO₂ impact in one step to optimize material and process decisions — from early design through supplier selection.

.png)

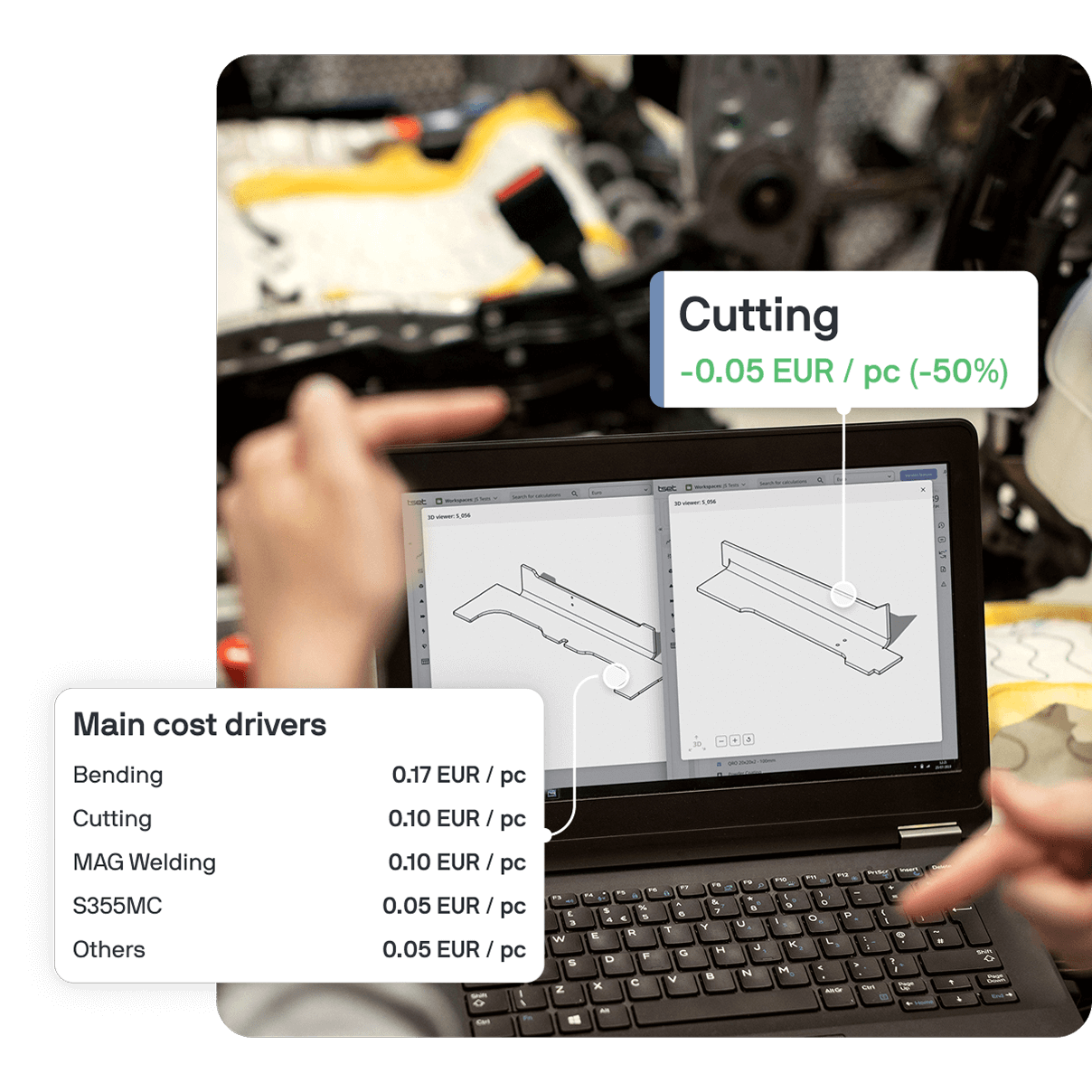

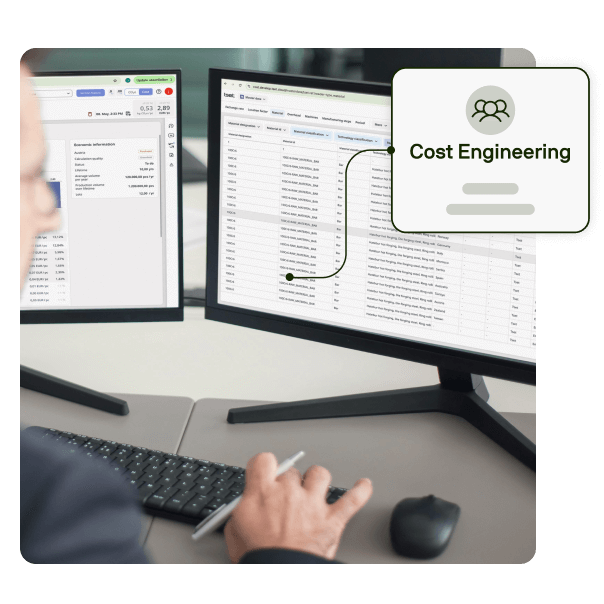

Automate Costing Without Giving Up Control

Run accurate cost calculations from teardown BOMs in under a minute. Built-in structures, cycle times, and market data ensure precision from the first click.

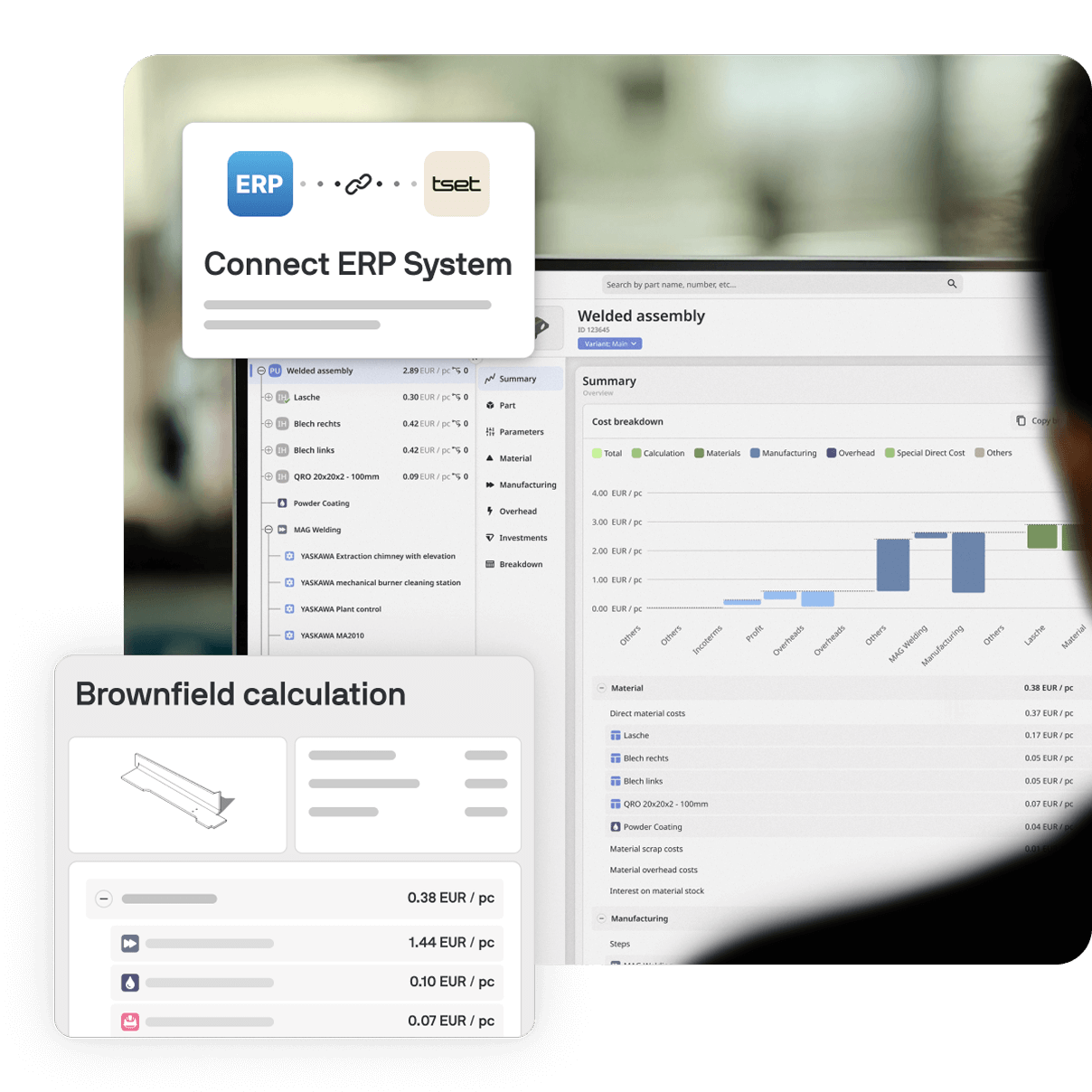

Ensure Consistent Cost Estimates Across Teams and Sites

Apply standardized assumptions and shared data sources to get reliable results. Easily compare costs across prototypes, suppliers, and global locations.

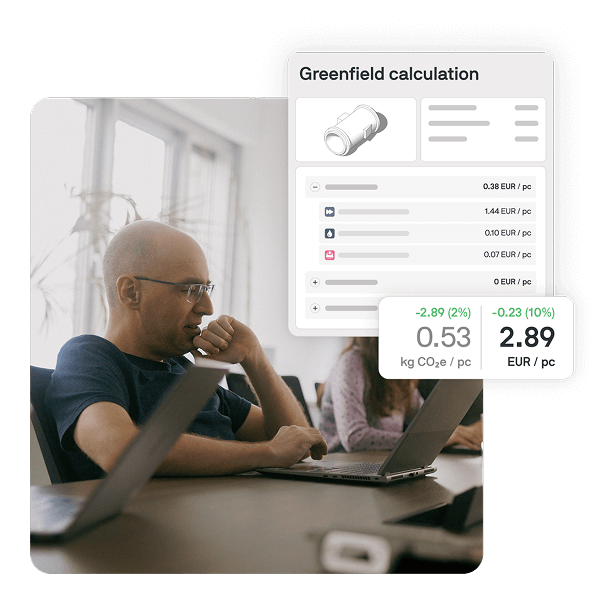

Integrate Cost and CO₂ Analysis From Day One

Combine cost and carbon footprint in a single calculation. Support sustainability goals while identifying savings through smarter material and process decisions.

Bridge Procurement, R&D, and Cost Engineering

Bring all teams onto one platform. Shared logic and full transparency enable faster, data-backed decisions from early development to sourcing.

Reduce Admin Work and Onboarding Time

Work with an intuitive interface, clean workflows, and automated updates. New users ramp up quickly, and your team spends less time on maintenance.

"The Tset software creates a solid basis for successful decisions in product development. At the same time, we can keep an eye on our CO₂ emissions and identify environmentally friendly solutions with no additional effort. The fact that we can systematically and automatically calculate the carbon footprint of our machine, and even of individual machine components, makes the Tset software the ideal solution for our requirements."

-

Supplier Negotiations

-

Design Decisions

-

Project Cost Control

-

Quoting That Wins

-

Build Up Cost Engineering

Understand supplier cost structures to negotiate better deals.

Use market data and cost models to gain transparency, compare supplier quotes, and negotiate with confidence.

Make cost and CO₂ part of early design decisions.

Evaluate cost and carbon impact early to compare design options before decisions become locked in.

Keep projects on budget and aligned with business goals.

Track cost and CO₂ from concept to launch to avoid overruns and stay aligned with targets.

Quote faster and more consistently, backed by real cost insights.

Support fast, confident quoting with consistent cost and CO₂ estimates based on real data and proven models.

Build up Cost Engineering with expert support.

Get hands-on support from Tset’s cost engineers and manufacturing experts to build your cost and CO₂ strategy, embed best practices, and deliver measurable savings across your organization.

Explore other resources

The Hidden ROI of Cost Engineering Tools

This guide shows how modern product costing software like Tset helps reduce manual work, improve collaboration, and uncover cost opportunities hiding in your current processes. Discover a clear, step-by-step framework to calculate ROI of a cost engineering tool and build a business case that gets management buy-in.

Ready to Automate Your Machinery Costing?

Let’s talk about how Tset helps you reduce admin time, improve accuracy, and meet CO₂ and cost targets — all in one solution.

.png)