Costing Without Complete Data: How Cost Engineers Can Ensure Accuracy Despite Missing Inputs

Germany’s manufacturing sector ended 2024 in a downturn that was difficult to ignore. The HCOB Manufacturing PMI dropped to 42.5 in December, a level that not only confirmed contraction but marked the 18th straight month of decline, according to Reuters. Across key industries, factories were producing less, backlogs were shrinking, and the outlook remained bleak. At the same time, European energy markets stayed volatile, with electricity and gas prices rising unpredictably, while global commodity costs continued to shift week by week. In this environment, cost engineers need new ways to deliver reliable estimates earlier in the process, even when key data points are still missing. Specialized product costing software can offer a structured approach to modeling cost under uncertainty, thereby helping teams move forward faster without sacrificing calculation accuracy.

The Traditional Process No Longer Fits the Pace of Change

The disruptions across the industry are not only affecting day-to-day operations but also changing how companies make product and sourcing decisions. According to KPMG’s 2024 Global Procurement Outlook, 83% of procurement leaders cite inflation and commodity price volatility as their top external concern. These conditions make it harder than ever to base cost estimates on stable, confirmed inputs.

Timelines are tightening, and design iterations are accelerating. In sectors like automotive and industrial equipment, products are often developed in parallel with sourcing and quoting. A recent McKinsey study found that more than 60% of product cost decisions are now made before specifications or suppliers have been finalized. As a result, cost engineers are pulled into the process earlier than before, but they are often working with only partial knowledge of the final design, production setup, or the supply chain.

This creates a disconnect that traditional costing methods cannot resolve. Engineers are expected to support early decisions with numbers that hold up in later negotiations, even when the underlying data is incomplete or in flux. Without the right tools, the risk of rework, misalignment and supplier challenges grows.

To close this gap, more and more manufacturers are turning to simulation-based costing. These tools allow models to evolve over time while maintaining a clear structure and audit trail, thereby ensuring that even early estimates can support real-world decisions.

From “Best Guess” to Structured Simulation

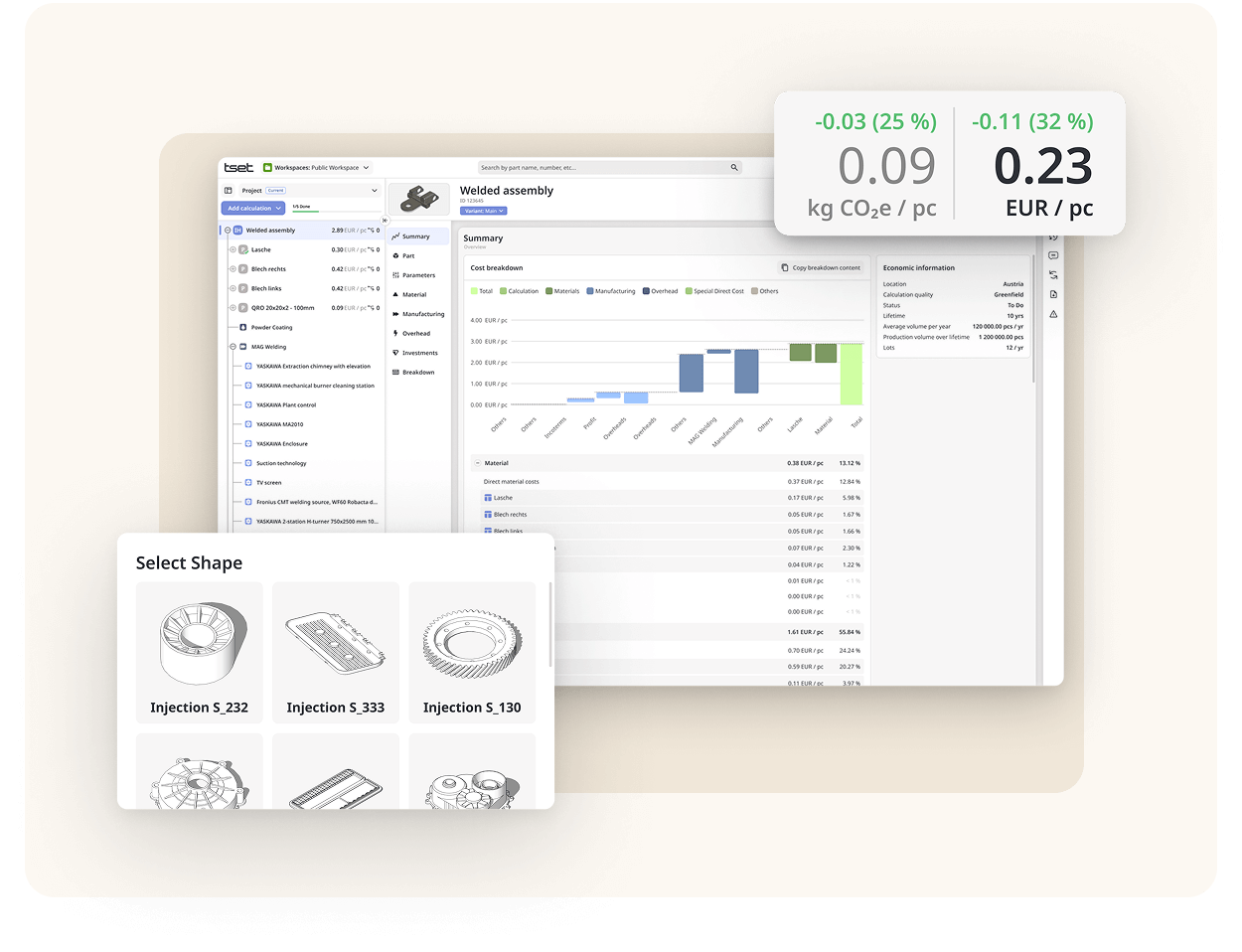

The key question is no longer whether engineers should wait for perfect data, but whether they can make confident, structured comparisons based on what they have today. This is exactly where product costing software brings value. It enables teams to build cost models on realistic assumptions, then refine those models as better inputs become available, preserving consistency from concept through sourcing.

According to Tset experts, users often begin calculating even when only 60 to 70 percent of the input data is available. This figure may sound low, but it reflects the new pace of decision-making. Business cases need to be evaluated, sourcing strategies need direction, and product concepts need feedback – irrelevant if all the details have been confirmed.

What does that 60 to 70 percent actually mean? Typically, early inputs might include:

-

Preliminary geometry

-

Expected volume

-

General technology process group (e.g., casting, machining)

But final data, such as supplier rates, detailed logistics, or tooling specifics, is still missing.

To make progress, teams use product costing software to begin with a “greenfield” estimate. This represents an ideal production scenario using best-practice cost and CO₂ data. Once internal constraints or supplier limitations are known, the estimate then evolves into a “brownfield” model, which reflects real-world production conditions.

KTM Brings Structure to Product Costing with Tset

Read how the leading motorcycle manufacturer KTM moved away from Excel-based cost models to Tset’s centralized platform—bringing consistency across R&D and Controlling. With Tset, KTM can now compare greenfield and brownfield cost simulations to identify real savings potential and make confident, data-driven decisions.

A Faster Approach Does Not Mean Cutting Corners

With the right simulation-based approach, quoting early can actually improve both speed and quality over time. Modern cost engineering tools like Tset are built specifically for this. They allow cost engineers to create structured estimates from the very beginning of a project, even when information is still evolving. Instead of waiting, engineers can already:

-

Build early cost models using templates based on real manufacturing processes

-

Document assumptions clearly to create transparency

-

Update and refine calculations as better inputs become available

You don’t need perfect input to create a useful estimate. What matters is your ability to compare options and see the consequences of your assumptions.

Why This Process Holds Up Under Pressure

Several features make simulation-based costing with Tset more reliable than traditional spreadsheet-based approaches:

-

Pre-built cost modules reflect real-world manufacturing logic, including process-specific cycle times, labor rates, machine usage, and energy consumption

-

Industry best-practice data fills gaps when specific values are missing, which can later be substituted with supplier quotes or internal rates

-

A standardized structure ensures that early estimates follow consistent logic across teams and product categories

Traceability Builds Confidence

What truly sets this approach apart is its traceability. Every adjustment, override, or change made in Tset is tracked and versioned automatically. Six months after a quote is submitted, a buyer or engineer can review:

-

Which assumptions were made

-

How material and process costs were calculated

-

What version of the product data was used

This level of transparency is nearly impossible to maintain using Excel or other legacy tools, particularly in organizations where multiple departments such as Engineering, Procurement and Finance are all involved in the costing process.

Conclusion

Manufacturing is accelerating, but so too are the expectations and demands on cost engineers. Businesses still demand transparent, logical, and reliable cost estimates - only now they need them earlier, and often before the data is complete. To meet these demands, cost engineers must work with structured assumptions, compare scenarios, and refine their models as new information becomes available. Product costing tools like Tset support this shift by helping teams manage uncertainty with speed, clarity, and control.

Incomplete Data Slowing You Down?

If your team is still waiting for stable inputs before quoting, it’s time to rethink that strategy. Tset helps you quote smarter, simulate faster, and act with confidence.