Cost Efficiency & Injection Moulding

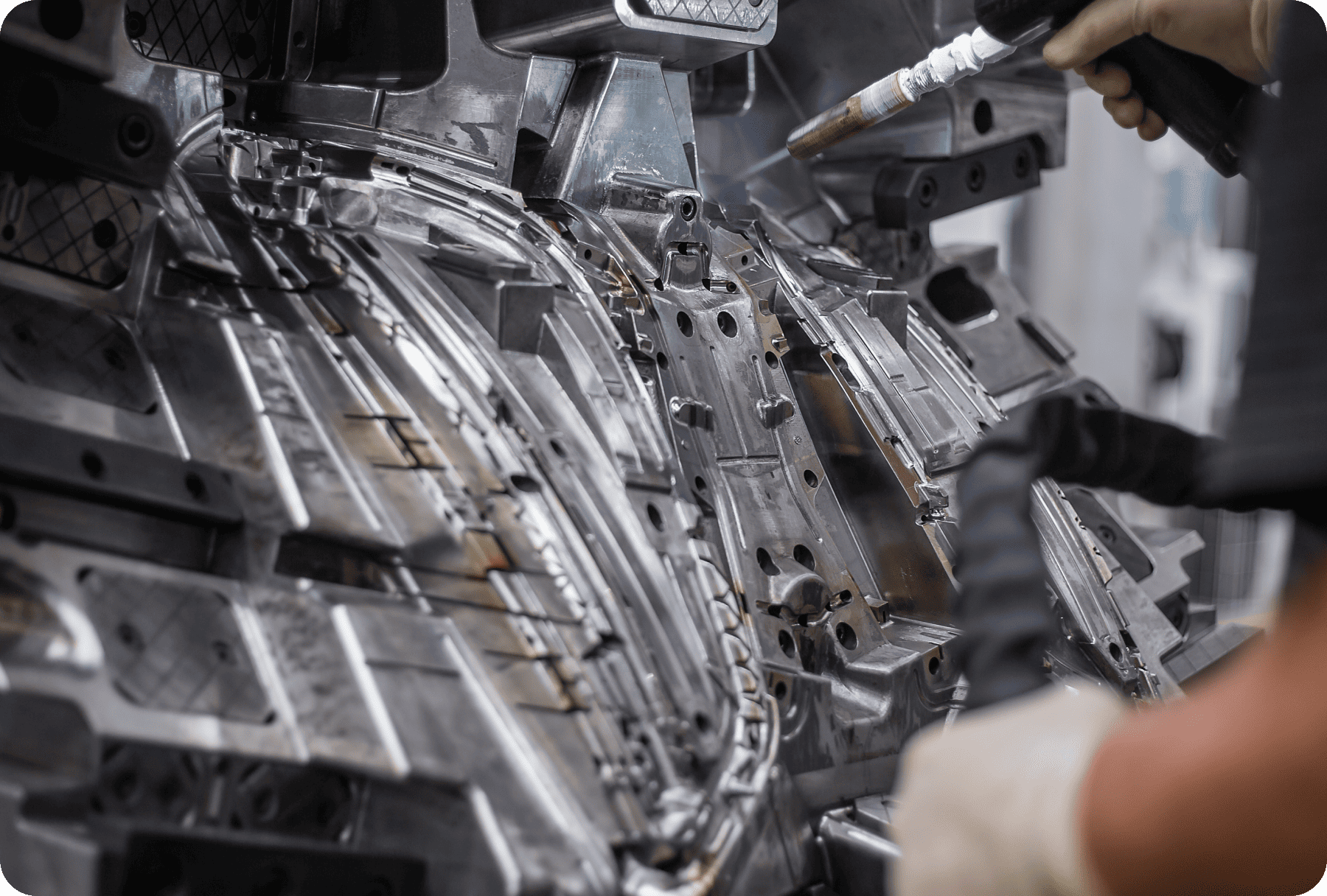

Injection moulding is used as a manufacturing process in a wide range of industries - whether automotive, consumer goods or electronics. Read our first publish of our "Tset tech module series" about Injection Moulding to deep dive into what exactly this method is, and how our software can help you in this process.

About this guide

This whitepaper is built for manufacturing leaders, cost engineers, and sourcing professionals working with injection moulded components. It provides a clear, practical look into how software-based cost management transforms complex injection moulding calculations into fast, data-driven decisions.

From tooling costs and cooling times to part geometry and sustainability goals—discover how modern costing platforms like Tset help balance technical feasibility with commercial viability, ensuring efficiency from early development to production.

Your takeaways at a glance

- The critical factors influencing the cost structure of injection moulded parts—from wall thickness to gating systems and material selection

- How Tset’s software models full production cells and dynamically simulates cost and CO₂ impacts across variants

- Why traditional costing methods fall short in capturing the complexity of injection moulding processes

- How manufacturers use Tset to run real-time simulations, reduce emissions, and identify cost-saving opportunities early in development

Explore other resources

Demo: Injection Moudilg

Whether automotive, consumer goods or electronics - injection moulding is used as a manufacturing process in a wide range of industries.

A Practical Guide to Cost & Competitive Positioning

Automate Bottom-Up Cost Calculation with Tset’s Product Costing Software

Smarter costing for every moulded part

Looking to optimize part design, reduce tooling costs, or cut CO₂ in your injection moulding processes? Our team can show you how Tset’s software delivers precise, simulation-based insights in seconds.