Dräger's Journey to 66% Transport Reduction and CO₂-Integrated Decisions with Tset

Dräger, a global leader in medical and safety technology, needed to improve how cost, CO₂ emissions, and packaging decisions were made early in development. With limited internal resources, they adopted Tset to support target costing, packaging optimization, and CO₂ transparency. The results were significant: faster simulations, smarter sourcing, and major sustainability gains, including a 66% reduction in transport volume and simplified CO₂-informed decision-making.

About Dräger

Dräger, a leading global provider of medical and safety technology, has long been recognized for its commitment to innovation and sustainability. Headquartered in Lübeck, Germany, and operating in over 50 countries, the company employs around 16,500 people and generates over €3.4 billion in annual sales.

The Challenge

For Dräger, managing product costs and sustainability across a large and diverse product portfolio was growing increasingly difficult. Their value management team, a small group split across the company’s medical and safety divisions, was under pressure to provide accurate cost estimations and sustainability assessments in early development phases. Existing tools lacked the ability to support detailed simulations, especially when evaluating production alternatives in different regions.

At the same time, Dräger’s sustainability targets were tightening: the company had already reduced CO₂ emissions by over 30% since 2015 and aims to halve them again by 2030 - with full CO₂ neutrality planned by 2045. To meet these goals, environmental criteria such as material emissions, packaging design, and transport impact needed to be embedded into cost analysis from the start.

The Solution

Dräger began using Tset in late 2024, after transitioning away from a legacy target costing tool. The team was looking for a flexible SaaS solution that didn’t require internal IT administration and could adapt to the company’s wide range of manufacturing technologies.

From day one, Tset delivered fast onboarding, intuitive usability, and direct integration with Dräger’s sustainability and engineering workflows.

How Dräger Works With Tset

Dräger uses Tset to enable cross-functional decision-making across value management, engineering, and procurement. The software supports structural cost analysis, environmental-conscious design, and target evaluations across suppliers and various geographies.

Target Costing with Sustainability in Focus

One of Dräger’s early use cases with Tset focused on the chassis in their Evita breathing device. The part, manufactured in Southern Germany, was originally shipped in packaging that took up 40 liters of space for a part under one liter in volume.

The team used Tset to calculate the chassis's target price and CO₂ impact across different production scenarios. Tset's toggle feature, which switches seamlessly between cost and carbon views, enabled Dräger to implement environment-conscious decision-making from the earliest development stages. This side-by-side evaluation revealed that emissions from transport and materials were significantly higher for production in China versus Germany.

As you can see in the results and cost breakdown, which can be switched to a CO₂ breakdown, the chassis has a very high CO₂ impact. Tset helped us calculate the target price and target CO₂ emissions for this part. Tset integrates CO₂ calculations seamlessly. With the toggle switch I demonstrated, we can easily focus on sustainability.

The intuitive modeling allowed Dräger to upload a STEP file and simulate the full production process. “The program completed the calculation in minutes,” Christian Hilleke noted. Tset automatically built out the manufacturing steps for a laser-cut, bent aluminum part, while allowing manual customization such as adding the press-fit assembly of helicoils.

Packaging Optimization

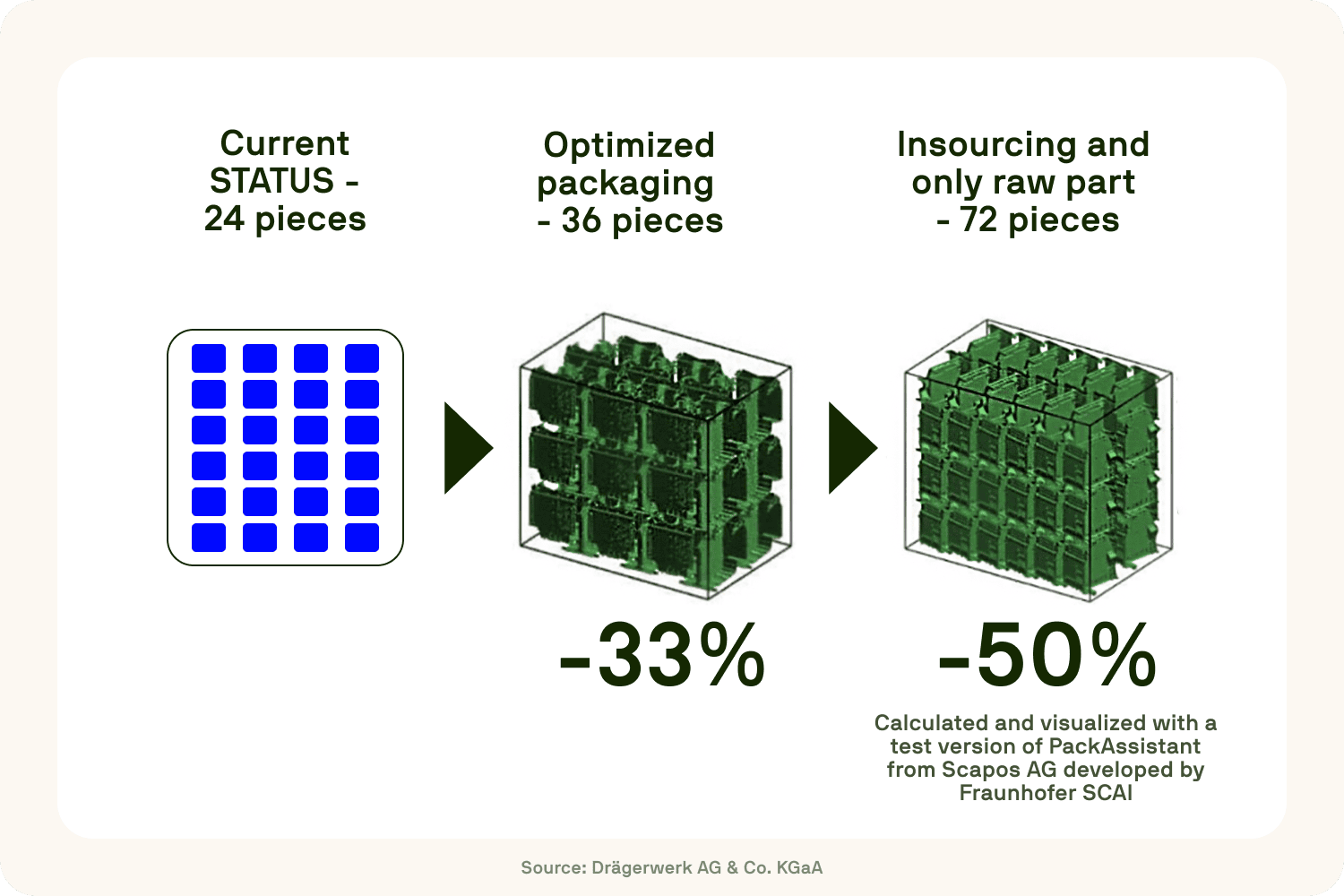

Packaging Optimization Sustainability at Dräger also includes packaging optimization - an area where Tset helped identify actionable improvements. Using the Inbound cost data from Siemens’ AX4 system, the team pinpointed excessive transport volumes due to inefficient packaging.

By redesigning the packaging layout and partially insourcing assembly, Dräger is able to increase part density threefold from 24 to 72 parts per box in some cases, therefore resulting in 66% lower transport volume. “This reduced transport volume by 66%, will result in four fewer trucks on German highways annually,” said Christian Hilleke.

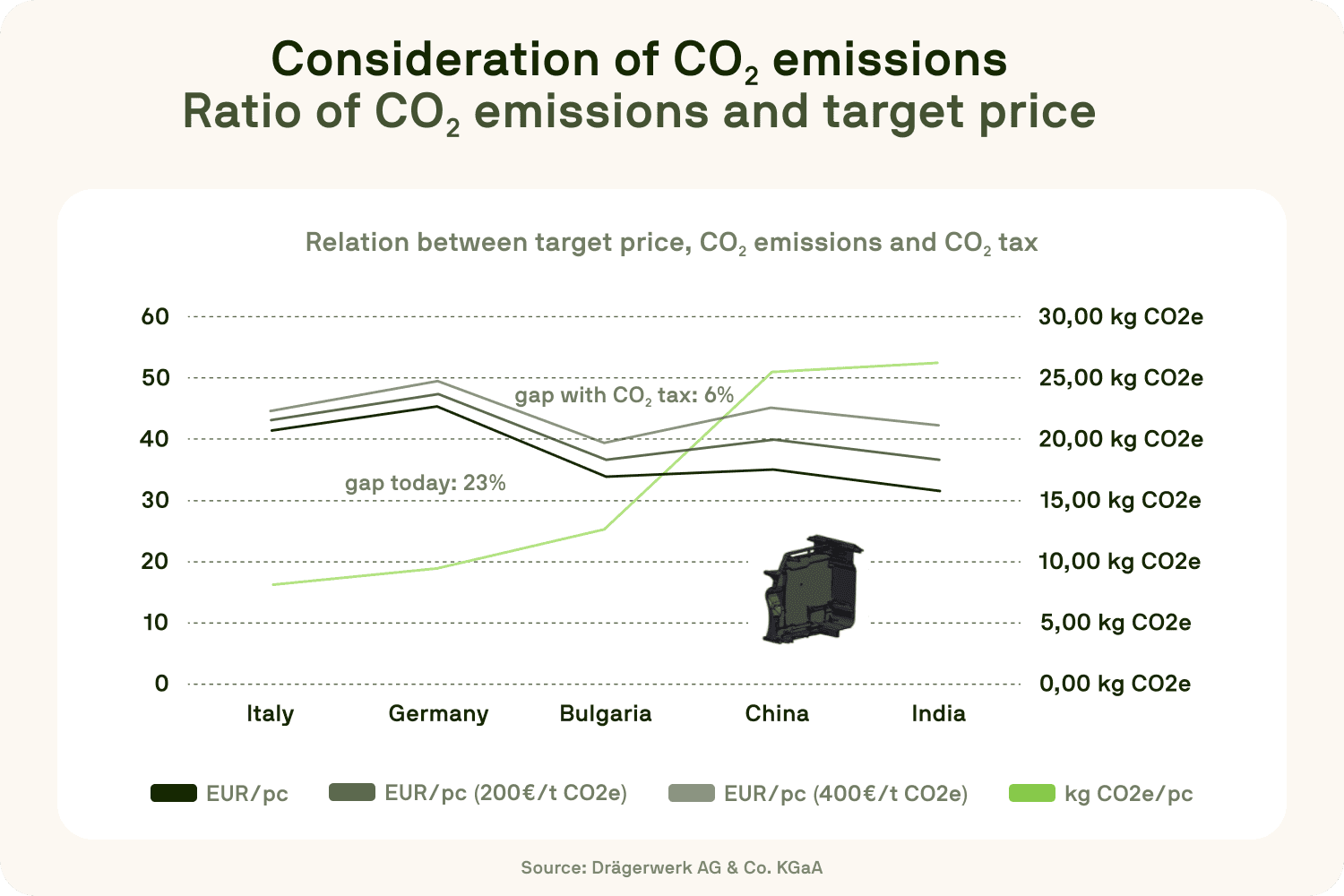

CO₂ as a Decision-Making Parameter

Beyond individual components, Tset supports Dräger in evaluating broader CO₂ impacts across geographies. "To promote sustainability, we must factor in CO₂ taxes. These taxes reduce the price gap and make local production more competitive. This is one way to integrate CO₂ emissions into product and supply chain decisions", says Christian Hilleke. For example, the company compared the emissions and costs of an aluminum die-cast part produced in Italy, India, and Germany. Italy offered the lowest CO₂ footprint, India the most competitive pricing, but once CO₂ taxes were factored in, the economic advantages of local production increased.

At a Glance: Key Benefits for Dräger

After seven months of use, Dräger’s value management team sees Tset as more than a costing tool - it’s an enabler of collaboration, transparency, and sustainability. With just three users split between the safety and medical divisions, a scalable and easy-to-implement SaaS solution was the key to solving Dräger’s challenges.

Tset proved to be the right fit for the company's unique product landscape and setup. Its strengths include:

- Better integration of CO₂ topics compared to competitors, helping Dräger align with internal sustainability goals.

- High compatibility with diverse product designs, from aluminum extrusion to micro injection and foam molding - many of which are not well supported by automotive-focused tools.

- Direct import and calculation from 3D STEP files, including nesting for materials like sheet metal.

- Seamless transition from former target costing software, enabling use of historic calculation data in the new system.

- Quick implementation of enhancements, with regular updates to meet evolving needs.

- Strong onboarding and support, ensuring the small team could become productive without external IT dependency.

- Feature development on demand, including new modules like Cost Break Down based on user feedback.

We now benefit from more frequent feature updates, allowing faster target price calculations and stronger CO₂ and cost optimization capabilities.

Read what other customers have to say

Get in contact with us

Discover our software solutions to see for yourself. We're happy to design an individualized package for your business upon request.