How to Achieve Transparency in Carbon Footprint Estimations in Early Product Development

As global awareness of climate change intensifies, the manufacturing industry faces increasing pressure from environmental concerns and governmental regulations to accurately measure and report their greenhouse gas (GHG) emissions. But how can companies effectively estimate their carbon footprint while ensuring transparency and accuracy?

The key lies in addressing this challenge early in the product development process. By integrating carbon footprint estimations into the early stages of design and planning, manufacturers can gain valuable insights that inform decision-making, optimize product sustainability, and ensure compliance with evolving regulations.

Understanding Carbon Footprint in Manufacturing

Greenhouse gases (GHG) are at the heart of climate change discussions. These gases trap heat in the Earth's atmosphere, contributing to the greenhouse effect. As human activities continue to increase GHG emissions, the need for the manufacturing industry to understand and measure their impact on global warming and climate change has never been more important than it is today.

To standardize this process, the World Resources Institute and the World Business Council for Sustainable Development introduced the Greenhouse Gas (GHG) Protocol. This protocol established a global framework for measuring and managing GHG emissions, introducing three distinct scopes that manufacturers must consider to reduce their environmental impact.

Let's break down these emission scopes and what they mean for manufacturers.

Scope 1: Direct Emissions

Direct emissions refer to direct greenhouse gas (GHG) emissions that a manufacturer produces through its own operations and assets. These emissions are directly owned or controlled by the organization. Common sources of Scope 1 emissions include:

-

Fuel combustion in company-owned or controlled boilers, furnaces, and vehicles.

-

Chemical production in owned or controlled process equipment.

-

Fugitive emissions from owned or controlled equipment and processes.

Scope 2: Indirect Emissions

Indirect emissions include GHG emissions that occur at the facilities where the energy is generated, rather than at the manufacturer’s own premises. Common sources of Scope 2 emissions are:

-

Purchase electricity

-

Purchased heating and cooling

-

Purchased steam

Scope 3: Indirect Value Chain Emissions

Scope 3 includes all indirect GHG emissions occurring in the manufacturing industry value chain; these emissions are connected to the company's business operations despite not being directly produced or controlled by the company. Scope 3 emissions can be either upstream or downstream:

-

Upstream emissions: Emissions related to purchased or acquired goods and services. Some examples include emissions from raw materials and components, transportation of purchased goods, business travel, waste generated in operations, etc.

-

Downstream emissions: Emissions related to sold goods and services, occurring after they leave the company's ownership or control. Examples could include the distribution and transportation of sold products, investments, franchises, etc.

Navigating Carbon Footprint Estimation Challenges

1. Governmental compliance

Meeting diverse reporting requirements, such as the GHG Protocol and CBAM, poses significant challenges. Companies must navigate complex regulations while ensuring data quality and methodology verification across their supply chain.

2. Working with data

Gathering accurate, timely data across complex supply chains is a significant hurdle. Manufacturers often struggle with incomplete or inconsistent information, especially for Scope 3 emissions.

3. Estimations accuracy

The manufacturing industry faces unique challenges in estimating future emissions for products still in development. Accurate projections are important but difficult to achieve because of evolving technologies and market conditions.

4. Technology stack

Many companies lack the appropriate software for analyzing, storing, and reporting carbon emissions data.

Early Estimation: The Key to Carbon Footprint Management

Having defined the different emission scopes, a crucial question emerges: how can we accurately estimate these emissions before it's too late? The answer lies in estimating carbon footprint emissions at the early stage of the product lifecycle. There are several reasons why this is the best strategy to follow.

Regulatory compliance

Carbon emission regulations like the EU's Carbon Border Adjustment Mechanism (CBAM) aim to put a fair price on carbon emitted during the production of carbon-intensive goods entering the EU. By estimating your carbon footprint early, you can better prepare for these regulations and avoid potential financial risks.

Optimizing product development

Early-stage carbon footprint estimation is most beneficial before production begins. At this point, you can still make significant changes to your product design. Tools for carbon and cost calculation, like Tset, are especially useful in these early stages of the product lifecycle, as they provide accurate estimations and allow for quick iterations. Carbon calculation software allows you to simulate different scenarios and immediately see the impact of design changes on your carbon footprint.

Improved supplier negotiations

Early carbon footprint estimation also plays a crucial role in finding the best targets, sourcing strategies, and supplier negotiations. This process involves two types of calculations: greenfield calculations and brownfield calculations. While greenfield calculations are estimates by cost engineers based on best-case, best-practices scenarios, brownfield calculations are more accurate figures based on “real-world data”. Cost and value engineers leverage these calculations to optimize designs and negotiate with suppliers, continuously refining carbon footprint estimates throughout the development process.

Transparency in decision-making

Early carbon footprint estimation creates transparency. Transparency in carbon footprint estimation provides strategic advantages beyond regulatory compliance. It enables informed decision-making, allowing companies to make sustainable and economical choices from the outset and gain a competitive edge in markets where sustainability is key.

How Tset Can Help

-

Simultaneous cost and carbon calculations: Transform manufacturing with Tset! Automate more, deliver faster and continuously improve your cost and carbon calculation at every stage of the product lifecycle.

-

Automated detailed bottom-up calculations: Tset comes pre-loaded with technology data-driven calculation modules, up-to-date reference data including material prices, energy CO₂ and prices, machine specifications, labor rates, and more. This comprehensive foundation fosters precise, automated bottom-up calculations while offering the flexibility to incorporate your own data for even greater accuracy.

-

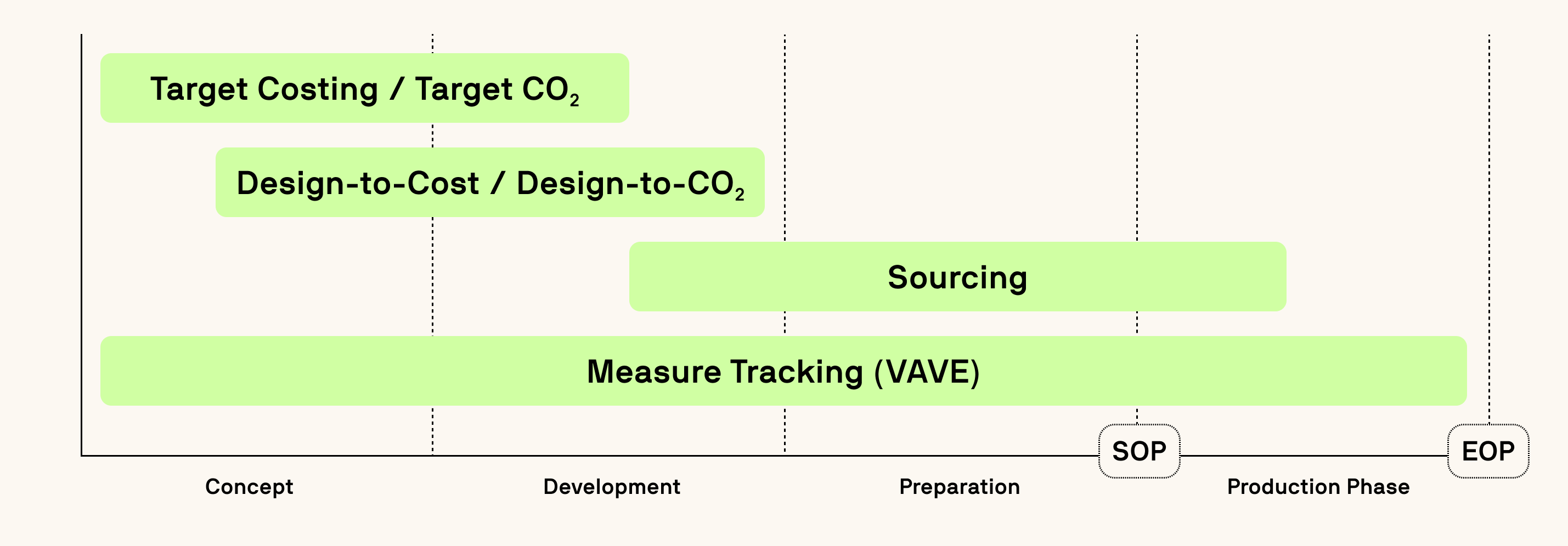

Lifecycle transparency: Tset offers transparent and comparable calculations throughout the product development lifecycle: from early-stage target costing and quotation to design-to-cost and carbon analysis, right through to should-costing - Tset provides consistent insights at every stage.

-

Quick adaptation: With Tset, implementing changes on the go is straightforward. This flexibility allows you to quickly adjust your estimations as new information becomes available or as product designs evolve.

-

Instant-on enterprise cloud solution: Tset offers a maintenance-free product cost, carbon footprint optimization, and management experience for a lower total ownership cost.

Conclusion

Early-stage cost and carbon footprint estimation is crucial for a manufacturing industry aiming to reduce its environmental impact and meet regulatory requirements. By leveraging software like Tset, manufacturers can gain valuable insights into their cost estimations and carbon emissions throughout the product lifecycle, enabling informed decision-making and more sustainable product development without losing money.

Would you like to know more?

For more information about cost and CO₂ engineering, read our whitepaper: "Carbon reduction in automotive supply chains". Explore the urgency of climate action and business resilience in more detail.