Cost Engineering: 3 Ways to Determine Manufacturing Costs

With rising costs and competitive pressures, cost awareness is crucial in modern engineering. Industries must carefully manage both existing components and new developments to maintain profitability. Setting cost targets and proactively managing costs is essential for successful product development today.

Cost Engineering is a hot topic and so we want to evaluate some questions:

-

Where do I get reliable feedback on how much a component in serial production will cost?

-

How can costs be managed in a very early stage in development departments?

-

And what tools can simplify the process of finding out the cost?

In general, I will talk about three practical methods of getting an indication of production costs:

-

Estimate

-

Rough calculation

-

Bottom-up calculations

Each method has its best-fit application with different pros and cons. The important factors are the timeframe you have for the estimation, how accurate it needs to be, and how many input parameters are already available.

The following chart gives you an overview of their strength and weaknesses.

Let’s have a closer look at all three options and the operational tasks behind them.

Estimate

With this approach, you can quickly estimate how much the part may cost based on comparisons with formerly purchased components that are similar in material, size, and shape. In the case that you can’t approach the purchasing department, you can ask a more experienced colleague about the price.

But what if the price estimates you get were poorly negotiated, or the assumptions provided by your colleague are outdated? A consequence is that you will expect the price to be in the range your colleagues told you, instead of actually knowing the true manufacturing costs of this part. A rough calculation may then help you get a better feeling for numbers.

Rough Calculation

With a rough calculation, you have at least some input parameters considered and have more reliable numbers. The manufacturing costs are determined by the material costs and production processes, which in turn define the manufacturing costs.

In this example, we will have a look at the material costs to get a feeling of what influence different materials can have on the overall manufacturing costs.

Let’s compare two calculations based on the parameters in the chart below: one made of aluminum, and one of steel.

As we can see, the use of aluminum increased costs by 103% compared to steel. We increased the volume of aluminum by 50% to compensate for the lower tensile strength. If we double the volume of aluminum to 100% compared to steel, the cost increase would be 171%.

If we make a rough estimate, the challenge is to catch the main cost drivers and get reliable and accurate data for that calculation. If you have poor data leads, such as wrong price assumptions for materials, you will get an inaccurate result with too low or too high expectations of the purchase prices.

Bottom-Up Calculation

The most accurate and advanced way to calculate the cost per part is to calculate them with a bottom-up approach. This is the most sophisticated and accurate approach, though traditionally much more time-consuming. However, with the right software, you can have the desired accuracy with the same time effort as that of a rough estimate. More on the software solutions later.

Up until now it was not clearly defined what is meant with manufacturing cost and what the purchase price in the end will be. The following chart will shed some light on this topic.

Bottom-up means that you use dedicated parameters like material prices, scrap rates, machines with dedicated hourly rates, as well as labor costs, overheads etc., to calculate the dedicated cost. This means you have to have a lot of parameters available, and they need to be up to date.

Here we have the same issue as with the rough calculation. Is your input data accurate and up to date?

Many companies still have Excel Worksheets as a single point of information and big data sets from previous products purchased. But is this the way we work in 2024?

Continuously updating input data for calculations, as well as ensuring correct and reliable calculation methodology for various production processes, is key to a reliable bottom-up calculation.

Here is an overview of the data required for a bottom-up calculation:

-

Calculation pre-conditions (Country, Volumes, etc.)

-

Material

-

Manufacturing Process

-

Machine

-

Labor

-

Tools

-

Overheads

These are just the top level components of a bottom-up calculation; there are many other parameters required in the finer details of each component.

How Tset Can Help

With modern state-of-the-art cost calculation software like Tset, you have all this data available and are always up to date. Tset uses best practice data from several verified companies and public organizations, depending on the data required.

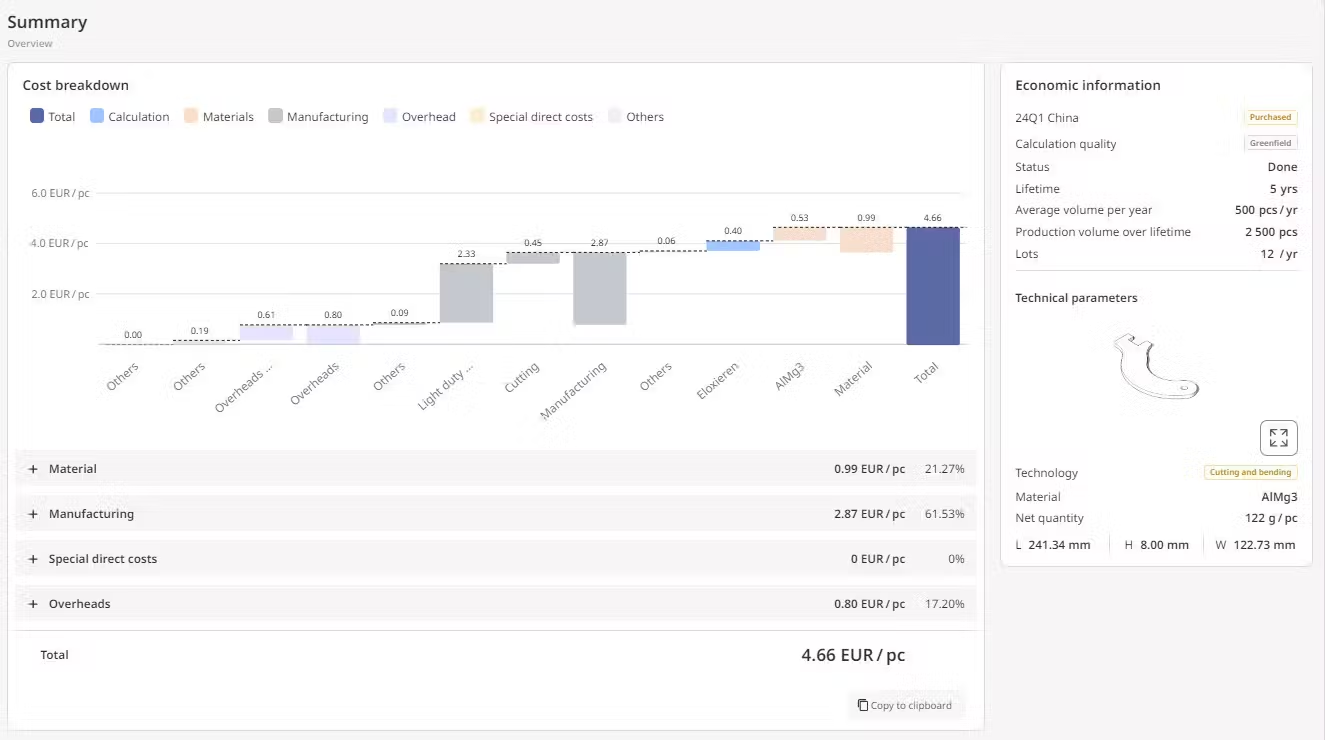

Not only is the required data much more detailed, but also the level of information gathered from such a calculation in Tset is much higher than other approaches. See the picture below.

With the information gathered from reliable and validated bottom-up calculations, you can already challenge the supplier’s offer, or just get detailed information on what your parts will cost when manufactured and what the cost drivers are.

Conclusion

Having discussed these three ways of cost determination, we can say that all approaches have their applications.

At the same time, if you use a modern cost engineering software solution like Tset, you can have a reliable best practice bottom-up calculation in the same time as a rough estimate.

Would you like to know more?

For more information about the challenges and trends around future-oriented cost engineering can be found in this whitepaper "Cloud, CO₂ and collaboration: The future of cost engineering".