Cost-Conscious CO₂ Reduction: Strategies for Sustainable Manufacturing

For manufacturers worldwide, balancing carbon emissions with the cost of production has become a critical focus. The rising costs of carbon emissions present a significant challenge, highlighting the urgent need for cost-conscious CO₂ reduction strategies in sustainable manufacturing.

The Rising Cost of Carbon: Global Pricing Trends

Governments worldwide are implementing diverse strategies for greenhouse gas pricing, including emissions trading systems, carbon taxes, and hybrid approaches. The coverage and pricing of these instruments vary significantly across jurisdictions, encompassing different emitters, gases, sectors, and locations. While no single jurisdiction currently achieves 100% coverage, some, like Sweden, combine multiple instruments to reach high coverage rates of 70-80%.

Looking ahead, carbon prices are projected to increase substantially over the next 5-10 years, potentially approaching the actual social cost of carbon. If this trend gains widespread support across jurisdictions, it will transform the manufacturing industry. Adapting to these rising price levies will become crucial for businesses to maintain competitiveness and sustainability in this evolving landscape.

Navigating the Regulatory Landscape

Beyond carbon pricing, which affects both organizational and product carbon footprints by increasing costs, there are various other instruments at play. These can be either voluntary or compulsory and may focus on either organizational or product carbon footprints. The implementation of such regulatory frameworks is particularly prevalent in Europe. For example, the European Union has introduced a taxonomy for green and brown business activities, providing a framework for sustainable economic practices. Additionally, the Carbon Disclosure Project offers a platform for organizations to report their carbon footprint. On the horizon, the European Union is developing a Digital Product Passport, which will require companies to disclose the environmental impact of their products throughout their lifecycle.

Key Approaches to Carbon Footprint Analysis

The four main approaches to carbon footprint analysis offer varying levels of accuracy and detail, each suited to different needs and resources:

-

Spend-based approach: This method estimates emissions based on financial data but has limitations in accuracy and granularity.

-

Net-weight-based approach: This method uses the weight of materials and applies standard emission factors, providing a more accurate estimate than the spend-based approach but still lacking in precision for specific materials and processes.

-

Net-weight-based with adjusted factors: An improvement on the standard net-weight approach, this method uses adjusted emission factors based on specific material properties or manufacturing processes, offering increased accuracy but requiring more detailed data.

-

Bottom-up calculation approach: This strategy is a golden standard in the industry, and provides more detailed and accurate carbon footprint assessments by analyzing individual components and processes. This method offers the highest level of precision and allows for targeted optimization of carbon reduction efforts.

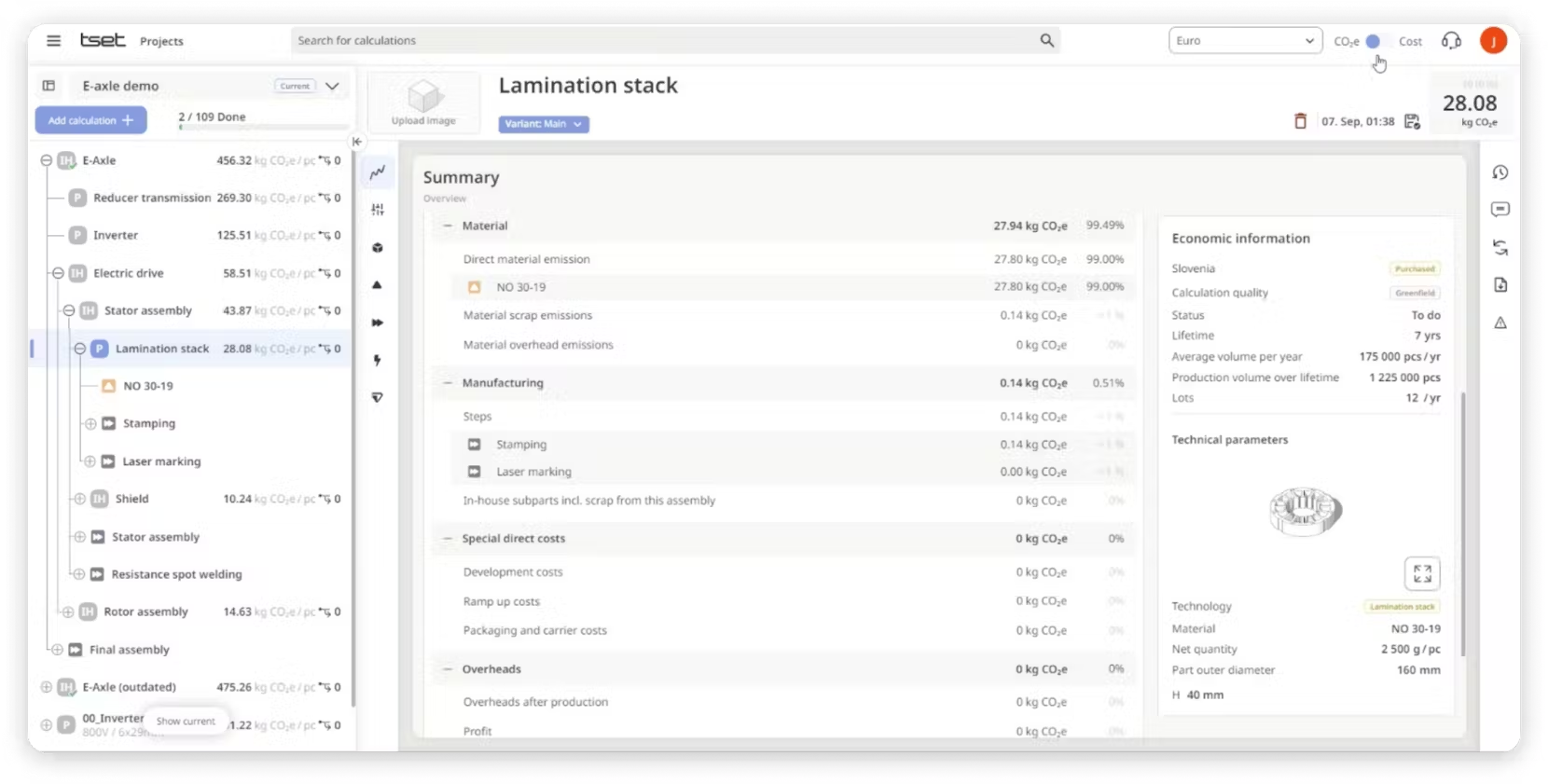

The cost and carbon calculation software Tset uses the bottom-up approach to provide a comprehensive analysis of product carbon footprints. This method describes in detail all raw materials, consumables, manufacturing steps, and associated parameters, integrating seamlessly with cost calculations by utilizing the same inputs. To support this approach, Tset maintains an extensive database of emission factors, ensuring effective and accurate carbon footprint assessments.

Real-World Impact: Tset's Case Studies in Carbon Reduction

The following examples illustrate the value of a detailed, bottom-up approach to simultaneous product carbon footprint and cost.

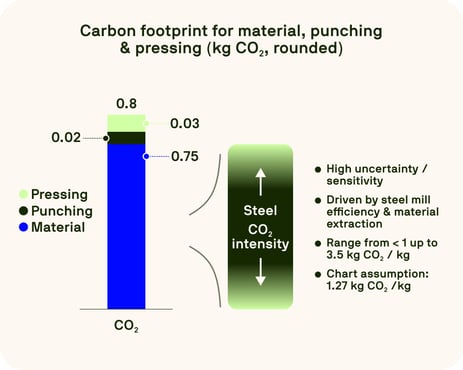

Example 1: Steel part - Raw Material Emissions/ Recycling Content

-

Material: Steel

-

Key factor: Raw material emissions

-

Outcome: The choice of steel type significantly influences the product's carbon footprint. Different steel production methods, such as Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF), can result in vastly different emission profiles, making the selection of lower-emission steel types crucial for reducing the overall carbon footprint.

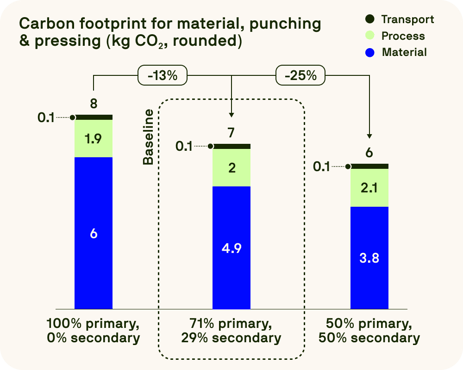

Example 2: Aluminum part - Raw Material Emissions/ Recycling Content

-

Material: Aluminum

-

Key factor: Recycling content

-

Outcome: Increasing the recycled content in aluminum can substantially reduce the carbon footprint of a product. By optimizing the recycled content, manufacturers can achieve notable reductions in carbon emissions.

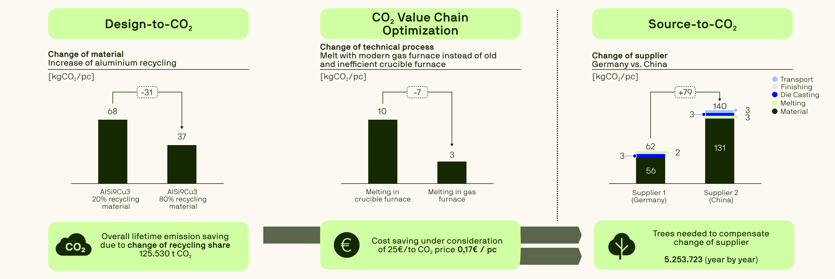

Example 3: Aluminum Casting - Combined Effects

-

Material: Aluminum

-

Key factor: Material, process, and location

-

Outcome: These three scenarios illustrate how material choice, manufacturing processes, and production location influence the carbon footprint of aluminum casting. Critical factors—including regional energy sources, casting efficiency, and aluminum procurement—significantly affect the overall carbon emissions. The combination of factors highlights the need for a holistic approach when identifying and implementing effective carbon reduction strategies.

Would you like to learn more?

For more examples and insights into carbon reduction in automotive supply chains, get a free copy of our whitepaper: "Carbon Reduction in Automotive Supply Chains".

Tset for Cost & Carbon Calculations

Tset offers a comprehensive solution for integrating cost and carbon calculations in product development. This innovative approach enables manufacturers to:

-

Perform detailed bottom-up carbon footprint calculations

-

Identify opportunities for simultaneous cost and carbon reduction

-

Make data-driven decisions to optimize product sustainability

By combining cost engineering expertise with carbon footprint analysis, Tset empowers companies to achieve their sustainability goals while maintaining profitability and business efficiency.

Watch the recording

Ready to dive deeper into sustainable manufacturing strategies? Watch the full recording of Jakob Etzel's talk from the Cost Engineering Global Conference to see a Tset software demo.

Conclusion

Detailed carbon footprint analysis is becoming increasingly crucial in product cost engineering. By integrating CO2 reduction strategies with cost considerations, manufacturers can achieve both environmental sustainability and economic efficiency. As regulations tighten and consumer awareness grows, companies that prioritize cost-conscious CO2 reduction will be better positioned for long-term success in the evolving manufacturing landscape.

Get in contact with us

Discover our software solutions to see for yourself. We're happy to design an individualized package for your business upon request.