Automotive manufacturers operate in a highly competitive environment shaped by technological shifts, regulatory demands, and global supply chain pressures. As electric mobility, digital vehicle architectures, and sustainability targets move to the forefront, the ability to understand and manage product costs quickly and accurately has become crucial.

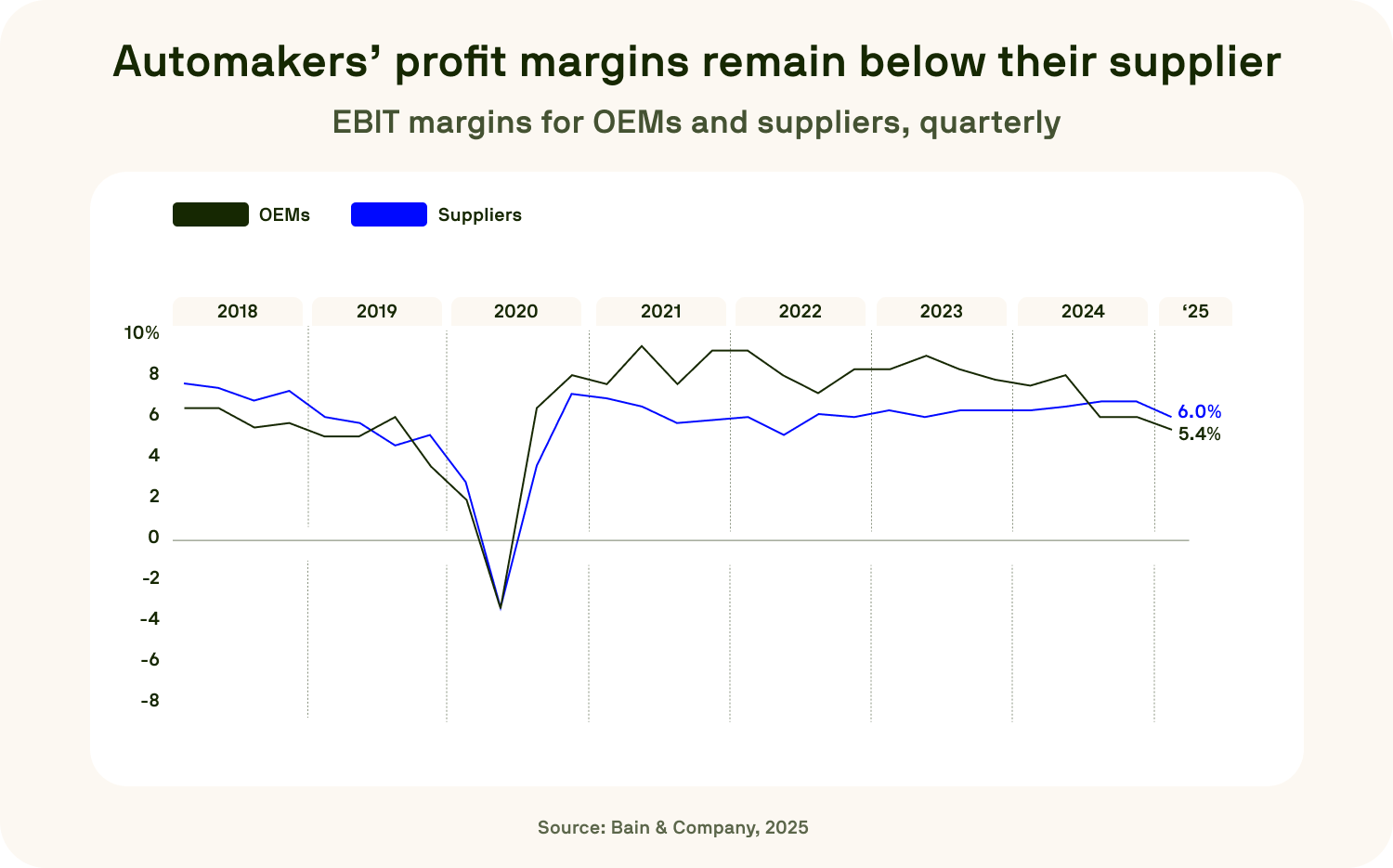

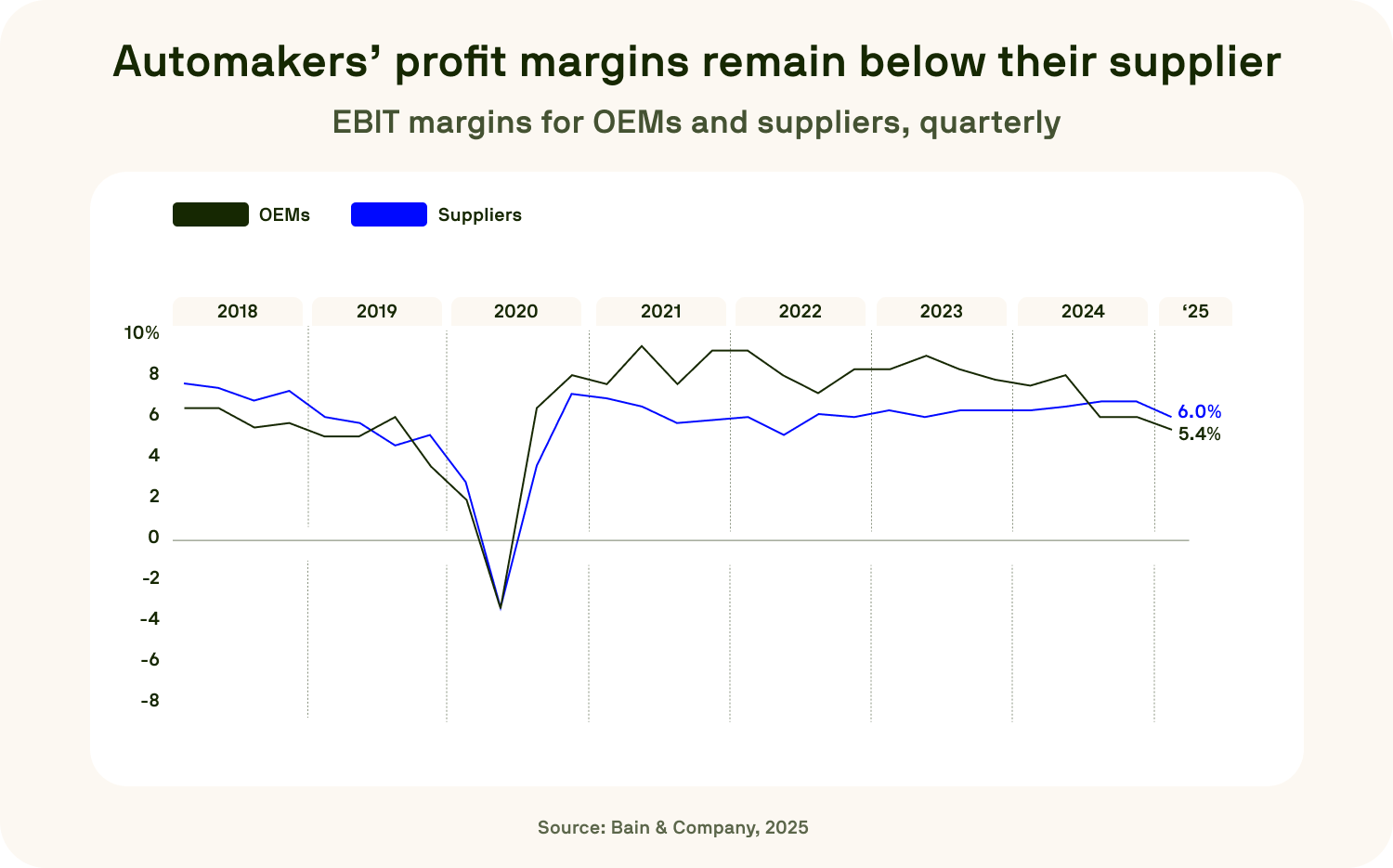

This challenge has taken on new urgency. According to Bain & Company, OEM profit margins dropped to 5.4% in Q1 2025 - a 40% decline from their 2021 peak and their lowest level since the pandemic. For the third quarter in a row, supplier margins outperformed those of OEMs, reversing nearly two decades of historical trends. With softening demand, rising interest rates, inflation-driven input costs, and potential trade tariffs, both OEMs and suppliers face intense financial pressure.

Product costing in the modern automotive influences design decisions, sourcing strategies, margin control, and much more. From quoting new business to responding to OEM demands for detailed cost and CO₂ breakdowns, teams are under growing pressure to deliver reliable calculations, often across complex product variants and global production footprints.

Yet despite this shift, many teams are still relying on tools that weren’t built for the scale, speed, or collaboration that today’s automotive industry requires.

Manufacturers continue to manage their costing in local spreadsheets or legacy solutions – the systems that are difficult to maintain, prone to errors, and heavily dependent on individual experts. Outdated workflows slow down progress, introduce risk, and limit the ability to challenge supplier prices or reduce costs across the lifecycle.

Automotive manufacturing and tool costs are often calculated manually, based on logic built years ago in Excel or legacy software. Costing expertise sits with just a few individuals, and when they’re unavailable, progress slows to a crawl. File-based systems lead to confusion over versions, lost changes, and inconsistent logic across departments.

It’s a pattern we hear again and again from cost engineers and buyers:

- "We spend too much time updating data manually instead of focusing on cost improvements.”

- “We can’t collaborate effectively using Excel - we lose track of changes and versioning.”

- “CO₂ data is being asked for more often, but we’re not equipped to deliver it.”

- “Our reference calculations are outdated, and we don’t trust the inputs.”

These issues cause delay decisions, weaken negotiations, and increase the risk of quoting with inaccurate or outdated assumptions.

In a high-stakes industry, slow and scattered costing processes cost more than time - they cost competitive advantage.

What Companies Want from Their Costing Solution

Automotive manufacturers are not looking for more spreadsheets or isolated point solutions. They want a cloud-based costing tool that calculates quickly, updates itself automatically, and supports collaboration across teams and locations.

They need to retain flexibility in calculations, without compromising on structure or data quality. Engineers want to adjust parameters and retain their internal logic, but they also want to rely on up-to-date reference data and automatic backups. Purchasing teams expect accurate supplier cost breakdowns that can be exported in specific formats. The CO₂ outputs should be generated alongside every calculation, not as an afterthought.

More fundamentally, companies are looking to build consistency across their cost engineering activities. Whether it’s quoting new business, analyzing purchased parts, or benchmarking against competitors, they want everyone to work from the same logic, with the ability to dig into the details and adjust as needed.