Brose is one of the fifth largest family-owned automotive supplier and one of the most innovative companies in Germany with numerous patent applications. At least one Brose product can be found in every third new vehicle. The company employs around 32,000 people at 68 locations in 24 countries.

How does Brose create more efficiency in product development and transparency of CO₂ emissions?

01.02.2024

Brose uses the Tset software. Thanks to this innovative solution, the automotive supplier shortens innovation processes and increases transparency regarding CO₂ emissions. Thus, Brose is taking its cost management to the next level.

(現時点では、カスタマーストーリーはENGとDEでのみご覧いただけます)。

About the Customer

The inital situation

In the automotive industry, as in other sectors, the combination of the lowest price and the highest quality determines who stands out amongst the competition. That is why strategic cost management is absolutely crucial. Impending costs must be kept in view right from the start of a project and ideally reduced and adjusted over time. At Brose, cost analysis is an integral part of cost management and begins with the target setting of a project. The company has been using professional software solutions for many years, but all the necessary data had to be entered manually.

"The early stages of product development are particularly important for us," explains Michael Flieger, Head of Cost Management Procurement at Brose. "If we have to make a new calculation for each variant, this naturally takes a lot of time."

Solution

Brose now relies on Tset to minimise time and workload and also measure CO₂ emissions. Our software calculates costs mostly automatically and simulates the CO₂ emissions caused by the production of individual components. This enables Brose to fulfil the new documentation rules of the European Union, which are intended to reduce the emission of climate-damaging gases.

From the start of product development to the final product, expensive changes and amendments can be avoided - without a great deal of labour. How does it work? It's child's play: select a component, enter parameters such as length, width and height - and realistic figures on material usage and scrap, cycle time, machine size and precise information on the probable unit costs and CO₂ emissions of the component appear.

We offer our cloud-based solution as Software as a Service and regularly test all the calculation modules. This guarantees easy implementation into your infrastructure and generates no internal IT costs.

Cost- and CO₂-analysis in detail

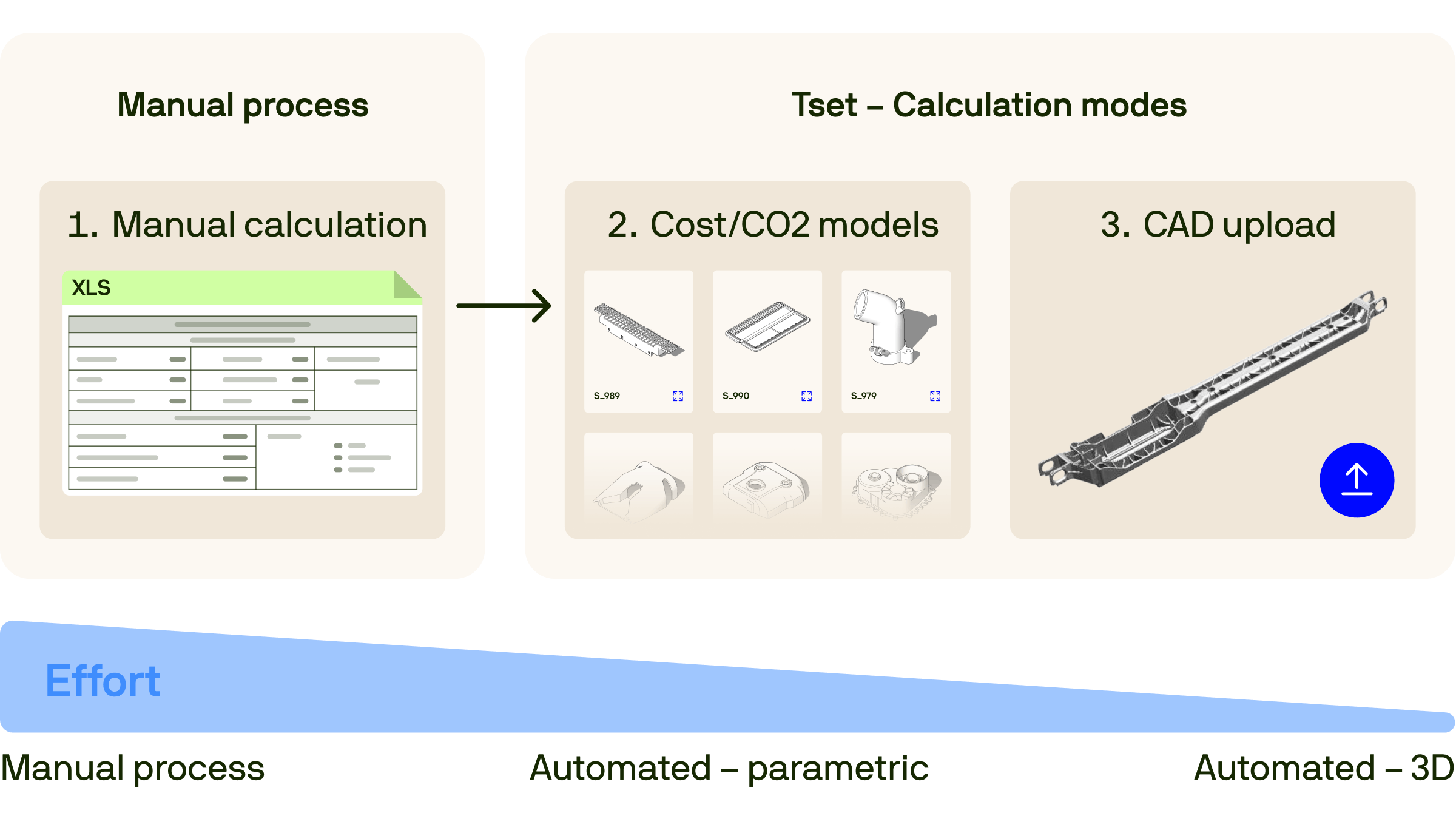

With our software, we offer Brose two time-saving alternatives to traditional manual cost analyses:

- Automated parametric calculation

- Automated calculation based on 3D-models

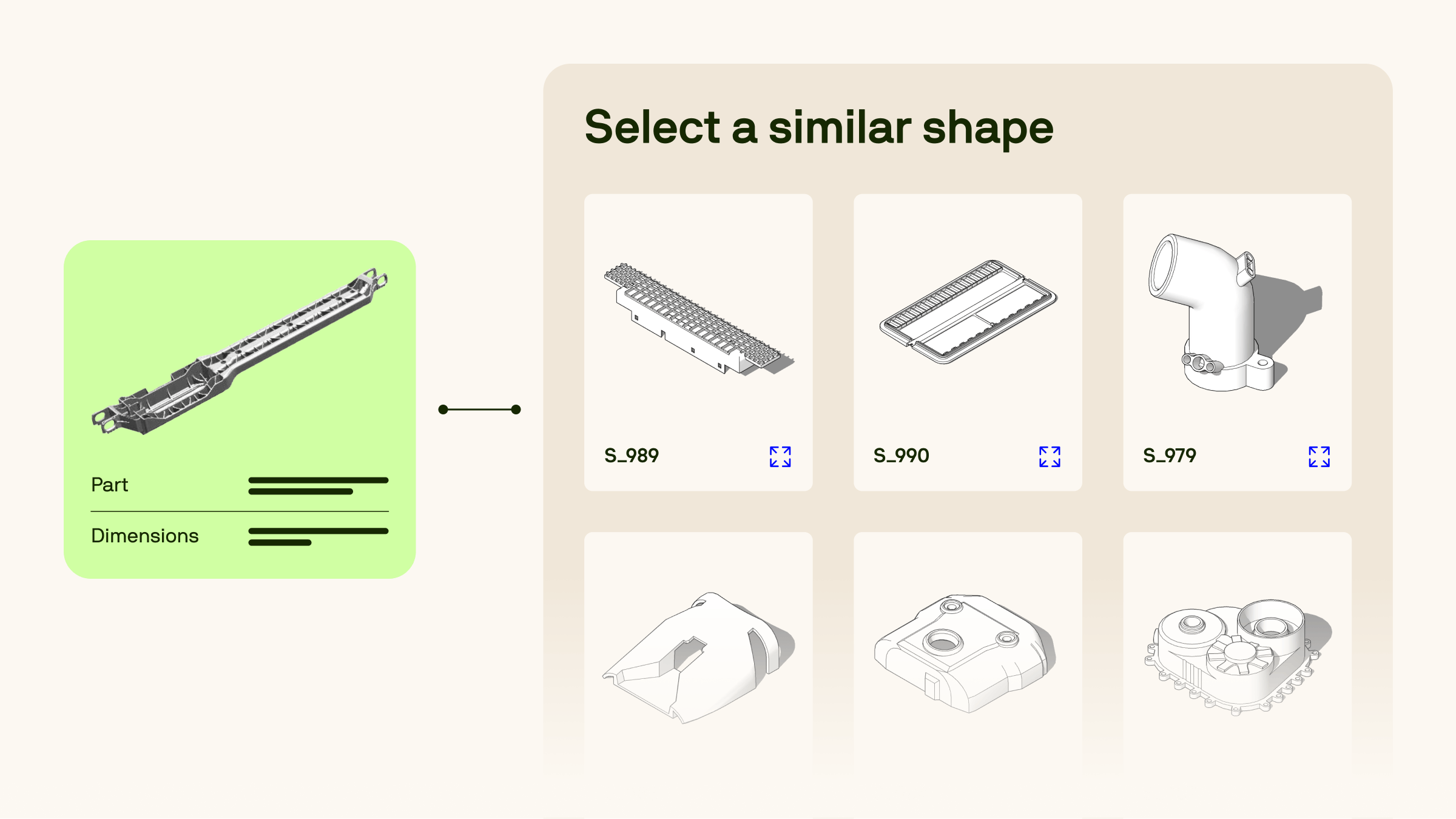

The illustration shows a parametric calculation using the example of a motor mount in a seat. The user can simply go to the "library" of the Tset software and select a similar object with similar requirements. He then only has to adjust a few parameters (weight, length, width, height) and the software calculates realistic values for cycle time, material usage, material waste, required machine size, etc.

"In this way, I receive a cost model with a very high degree of accuracy. The cost analyst can then adjust parameters to further improve accuracy or factor in unusual specifications. This is much faster than a bottom-up calculation for each component." ,Michael Flieger.

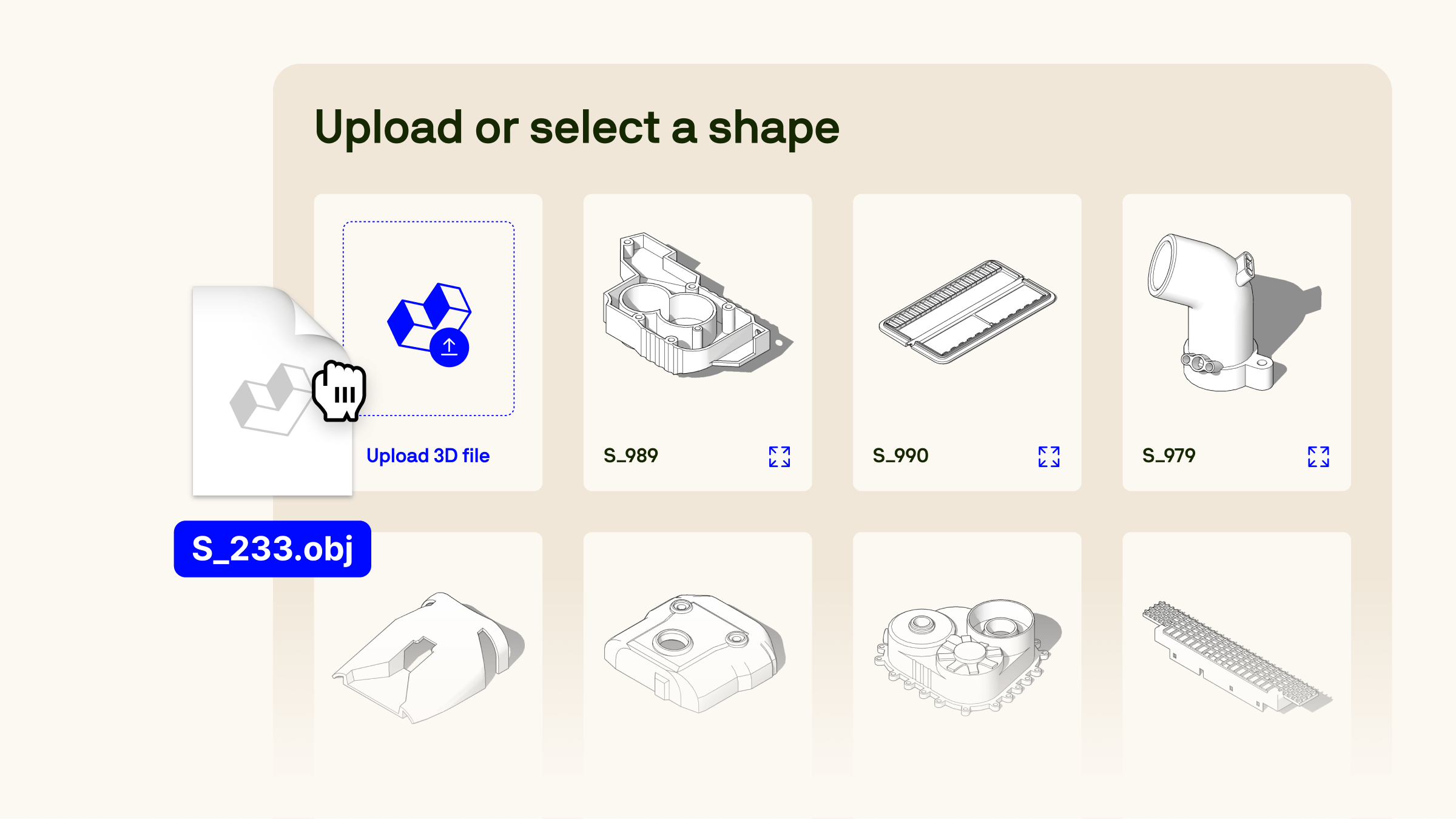

Equally beneficial is the 3D upload function (here using the example of a bent sheet metal part). With this option, the user simply needs to upload a 3D model in a common format to the software. The tool then automatically derives parameters from the 3D model and generates an unfolding (with part weight and insert weight). Within a very short space of time, the user receives a cost model that is highly sufficient for further utilisation.

"The 3D upload function is particularly fast. Not only do I get a calculated figure, but also a complete process simulation for the part, including a suitable setup, material costs, etc."

Michael Flieger, Head of Cost Management Procurement at Brose.

Both the costs for the desired component and a CO₂ footprint in kilograms (21 g CO₂ in the example of this sheet metal coil) are displayed in the software simultaneously. The CO₂ emissions emitted are broken down by raw material, process (and process details), electricity consumption and supplier-specific aspects (e.g. green power supply vs. standard energy supply). In this way, scenarios can be modeled while also comparing the costs of multiple technical solutions.

"The Tset software enables us to make decisions that also have a positive impact on the future carbon footprint of our products and the company."

Michael Flieger, Head of Cost Management Procurement at Brose.

At a glance – the advantages Tset holds for Brose:

Our collaboration with Brose started with a pilot project. Since then, Brose has become one of our investors. In Tset, Brose has found a partner that supports the company in gaining a competitive edge - both in terms of cost savings and climate protection.

"We were impressed not only by the software, but also by Tset's overall expertise. In Tset, we have found a process-oriented partner who supports us in accelerating and optimising innovations."

Michael Flieger, Head of Cost Management Procurement at Brose.

Listen to the full case study.

Learn how automation can empower your manufacturing endeavors and drive success. What strategies can manufacturing companies implement to effectively leverage automation for competitive and sustainable growth?