The Hidden Enemy in Costing Projects: How Fragmented Data Disrupts Sourcing Decisions

Sourcing success depends on accurate cost data, and yet in many manufacturing companies that data is scattered - locked in disconnected spreadsheets, outdated systems and departmental silos. Procurement calculates one way, while Engineering applies different assumptions and Controlling even relies on last year’s figures. Cost Engineers are stuck stitching together half-complete inputs, validating assumptions on the fly and chasing after numbers, all while RFQs continue to stack up.

This is the everyday paradox in cost engineering during sourcing: you’re expected to move fast, align across departments and defend your numbers – all while your input data is fragmented across tools, spreadsheets and teams. According to the Manufacturing Leadership Council, 70% of manufacturers still enter data into spreadsheets manually, and 68% still use them for data analysis. At the same time, 44% of surveyed manufacturers say their data volume has doubled in the past two years and expect it to triple by 2030. As a result, manufacturers deal with more data but actually have less trust in it. This explains why cost logic becomes inconsistent, collaboration breaks down and supplier decisions get made based on the loudest opinion, not the best data. And in a sourcing environment where margins are tight and timelines are short, that’s a serious risk.

The Real Impact of Disconnected Data

At first glance, data fragmentation looks like a few minor inefficiencies: version mismatches, missing data or an outdated cost model. But under pressure, these small gaps turn into major roadblocks. In manufacturing sourcing, delays aren’t just annoying - they’re expensive. Quote validations take longer; supplier feedback loops break down and internal alignment becomes harder to reach. That’s where fragmented systems quietly start to hurt margins and credibility.

Everyone is Using Different Numbers

When every team pulls from a different Excel sheet, quote email or ERP export, cost assumptions can quickly diverge. Engineering might model with a material price, while Controlling uses last year’s labor rate and Procurement negotiates based on a third benchmark. None of them are wrong, but they are not aligned. This kills trust in the final cost number and slows down sourcing decisions with unnecessary internal debates.

Time Lost to Data Chasing

Fragmented systems force Cost Engineers to act more like data managers than analysts. Hours are spent searching for supplier quotes and verifying material inputs, or formatting cost breakdowns to fit different reporting needs. This manual effort slows teams down and distracts them from more valuable tasks like scenario planning and quote validation. When data gathering takes longer than the decision itself, competitiveness suffers.

Close to 70 percent of employees spend upwards of 20 hours a week chasing information across different technologies instead of doing their job. In other words, employees are stuck spending up to half the average work week on “gray work”, which is creating ad-hoc solutions and workarounds to fit their needs when they run into roadblocks caused by fragmented tools, systems and processes.

Sourcing Moves Fast - Your Tools Don’t

RFQ timelines are short, but internal approvals tend to drag out when models need constant fixing. Buyers are forced to act without all the data, or without full alignment from Engineering and Controlling. The result is rushed sourcing decisions that lack cost clarity and often leave money on the table during negotiations.

Critical Cost Data Stuck in Silos

Data silos don’t just slow things down, they block critical information from flowing between teams. Engineering might track technical cost drivers, Procurement might follow supplier trends, and Controlling might model spend curves. But if these insights live in disconnected systems, none of them can drive better outcomes.

You Can’t Negotiate What You Can’t Explain

Without a consistent cost model, there’s no clear way to spot pricing outliers or justify why your number is more accurate than the supplier’s. You’re left with shaky logic and missed opportunities to push back. And when commodity prices shift or new quotes arrive, it’s nearly impossible to adapt quickly without rebuilding the whole model from scratch.

From Disconnected Data to Confident Decisions with Tset

At some point, all the disconnected spreadsheets, legacy ERP exports and team-specific workarounds stop being “good enough.” They slow down sourcing decisions, introduce errors and make it impossible to compare supplier quotes with confidence.

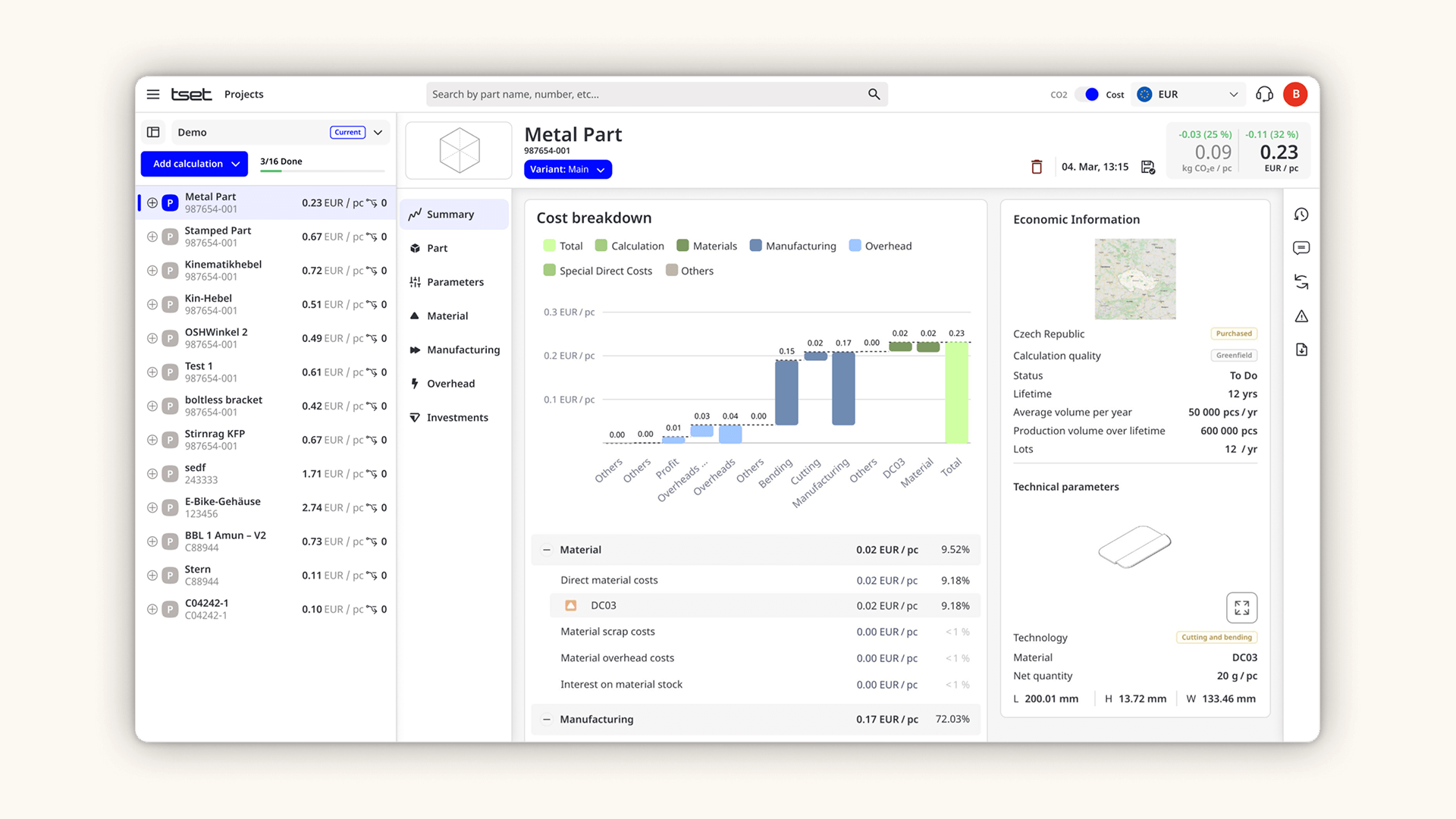

Tset’s product costing software replaces this fragmented approach with a centralized, cloud-based platform built for fast, consistent and technically sound product cost calculations.

-

Standardized logic: Everyone works from the same methodology - Procurement, Engineering and Controlling. No more merging Excel versions or reconciling inconsistent assumptions.

-

Automated cost breakdowns: Tset generates full bottom-up calculations using embedded data modules, thereby cutting modeling time from hours to minutes.

-

Up-to-date master data: Live material prices and secondary data integrations keep your cost models accurate and defendable during negotiations.

-

Variant and scenario management: Simulate make-or-buy, CO₂ impact and design variants in a single platform – all without rebuilding models from scratch.

-

No IT bottlenecks: As a cloud-native solution, Tset requires no internal IT or infrastructure setup. All updates, support and maintenance are handled as part of the license.

The Hidden ROI of Cost Engineering Tools

Still relying on spreadsheets and disconnected systems to make sourcing decisions? Get our free guide, "The Hidden ROI of Cost Engineering Tools", and see how centralizing your cost data changes everything.

Conclusion

When everyone uses different assumptions and scattered tools, sourcing decisions slow down and become hard to justify. You lose time chasing inputs, and it’s tough to explain where numbers come from. With product costing software like Tset, costing becomes consistent, faster to update, and easier to align across teams

Ready to stop sourcing in the dark?

Centralize your cost data, justify your numbers, and make better sourcing decisions with modern product costing software. See how Tset can change the way you work.

1. What is fragmented cost data?

Fragmented cost data refers to information that is stored in multiple, disconnected tools, spreadsheets, or systems across departments. In manufacturing, this often means procurement, engineering, and controlling teams use different data sets, which leads to inconsistent assumptions and misaligned sourcing decisions.

2. Why is fragmented data a problem in product cost management?

When cost data is fragmented, teams work with outdated or conflicting numbers. This results in slower RFQ turnarounds, inconsistent should-cost estimates, and difficulty justifying supplier negotiations. According to industry research, 70% of manufacturers still rely on manual spreadsheet entry, making alignment across departments nearly impossible.

3. How does fragmented data impact sourcing decisions?

Fragmentation introduces delays and errors in quote validations, causes internal misalignment, and reduces confidence during negotiations. When teams use different cost logic, decisions are based on assumptions rather than facts - putting margins and credibility at risk.

4. What are the signs your costing process is suffering from data fragmentation?

Key red flags include:

- Repeated rework of cost models

- Multiple versions of the same quote

- Manual data clean-up before RFQ responses

- Inability to trace or explain cost assumptions

- Frequent disagreements between departments over the “right” number

5. What is the benefit of centralized costing during supplier negotiations?

With centralized, structured data, you gain:

- Faster cost model updates in real-time

- Clear justification of each cost driver

- Confidence when pushing back on supplier quotes

- The ability to compare quote scenarios quickly without manual rework