How Product Cost Benchmarking Drives Market Positioning

The term “benchmarking” often brings to mind a narrow focus on cutting costs - trimming materials, reducing production expenses, or simply making products cheaper. While these outcomes may be relevant, they only scratch the surface of what benchmarking truly offers in a modern manufacturing context.

Today, product cost benchmarking is emerging as a critical strategic tool. It plays a vital role in aligning design and sourcing decisions with market expectations, shaping competitive pricing strategies, and guiding cross-functional teams through data-informed development processes. For cost engineers, procurement specialists, and product managers alike, this discipline offers far-reaching value that goes well beyond conventional cost-cutting.

In this article, we will explore how product cost benchmarking drives market positioning of your product. You will learn what it is, why it matters across departments, and how modern product costing software transforms benchmarking into a collaborative, high-impact business function.

What is Product Cost Benchmarking?

Product cost benchmarking is a structured methodology for comparing the cost structure of a product against competitors, market standards, or internal best practices. At its core, it helps organizations understand whether they are spending too much, too little, or just enough for the value their product delivers. More importantly, it allows them to break down these costs into actionable insights.

This type of benchmarking does not stop at high-level price tags. Instead, it enables manufacturers to drill into the details - including material selection, process steps, labor distribution, and overhead allocation. By doing so, companies can identify inefficiencies, expose hidden opportunities, and uncover the real drivers behind their cost structures.

Ultimately, the true strength of product cost benchmarking lies in its ability to support strategic decision-making. Through a detailed understanding of both internal and external cost factors, businesses are better equipped to align their product offerings with customer expectations and competitive pressures.

Reflecting Your Competitive Position: Why Motivation Matters in Benchmarking

Before diving into tools and technologies, it’s important to understand why benchmarking is relevant in the first place. Benchmarking should never be performed in isolation or as a one-off exercise. Instead, it should be tied to a company’s strategic position in the market and the specific phase of the product lifecycle.

A cost benchmark for a mature, price-sensitive product will differ significantly from that of an early-stage innovation or a niche technical component. Your motivation for benchmarking - whether it is to improve supplier negotiations, validate design trade-offs, or support portfolio optimization - shapes the methodology you should apply.

Product cost benchmarking helps you make the right decisions at the right time, ensuring that actions across engineering, procurement, and product management reflect your company’s goals and the competitive environment in which you operate.

Aligning Benchmarking with Market Positioning

Benchmarking plays an essential role in helping companies position their products effectively in a competitive landscape. It goes beyond assessing whether costs are “too high” by asking whether those costs are appropriate for the value being delivered. In a market where customer preferences, regulatory standards, and innovation cycles are constantly shifting, this level of alignment is essential.

Starting a product cost benchmark, the right way unlocks great opportunities, providing valuable insights into product potential and future growth.

A comprehensive benchmarking effort considers both external and internal dimensions. On the external side, manufacturers can assess how their products stack up in terms of pricing, technical performance, and perceived value. Internally, they can analyze existing product portfolios, historical performance data, and supply chain configurations to determine how strategic each product truly is within the broader offering.

This dual-perspective analysis helps organizations define their optimal market position. It ensures that design choices, sourcing strategies, and pricing models are not made in isolation but reflect real-world dynamics. Without such an approach, companies risk overengineering their products or, conversely, failing to meet essential customer requirements.

Benchmarking playbook for cost engineers

Get a structured, step-by-step approach to benchmarking in our new guide: “A Practical Guide to Cost & Competitive Positioning". See how to define project targets, conduct teardown analysis, and use data for informed decision-making, explore our in-depth guide. Learn from a real-world case study.

Benchmarking as a Cross-Functional Process

One of the most common misconceptions about product cost benchmarking is that it is solely the domain of cost engineers. In practice, its benefits extend across the organization, informing decisions at every stage of the product lifecycle.

Product Development and Engineering

Engineers can use benchmarking insights to align technical requirements with market expectations early in the design phase. This ensures that products are not only technically feasible but also commercially viable. For instance, understanding that a competitor delivers similar functionality at lower cost may prompt rethinking of design elements or material choices.

Procurement and Supply Chain

Procurement professionals can use benchmarking data to strengthen supplier negotiations and validate quotes. By comparing supplier offers against industry-standard benchmarks, they are better positioned to challenge excessive costs and identify more efficient sourcing options. Integrating this with should cost analysis further enhances credibility during negotiations.

Sales and Marketing

In sales and marketing, benchmarking can clarify the unique selling proposition (USP) of a product by pinpointing where it stands out from the competition. Sales teams equipped with cost-performance data can make stronger arguments about value, especially when facing price-sensitive buyers.

Corporate Strategy and Business Development

At the strategic level, benchmarking supports portfolio optimization. It helps identify which products to phase out, which to enhance, and where to invest next. By grounding these decisions in data rather than intuition, companies reduce risk and improve long-term returns.

Why Legacy Tools Are No Longer Enough

Despite the growing importance of benchmarking, many companies still rely on outdated tools such as spreadsheets or rigid legacy systems. While these might suffice for simple calculations, they fall short when the task demands collaboration, transparency, and real-time data access.

Spreadsheets present significant challenges:

-

Difficulty managing complex BOMs or multi-variant product families

-

Lack of traceability for calculations or revisions

-

Collaboration issues leading to inconsistent results across teams

In large organizations, these issues translate into slow decision-making and costly errors. Without a central source of truth, benchmarking becomes fragmented, and opportunities for improvement are lost in translation.

The Value of Modern Product Costing Software

A modern approach to benchmarking requires more than just better spreadsheets. It requires a platform that integrates data from across the organization, provides real-time simulations, and supports collaboration among technical and commercial teams.

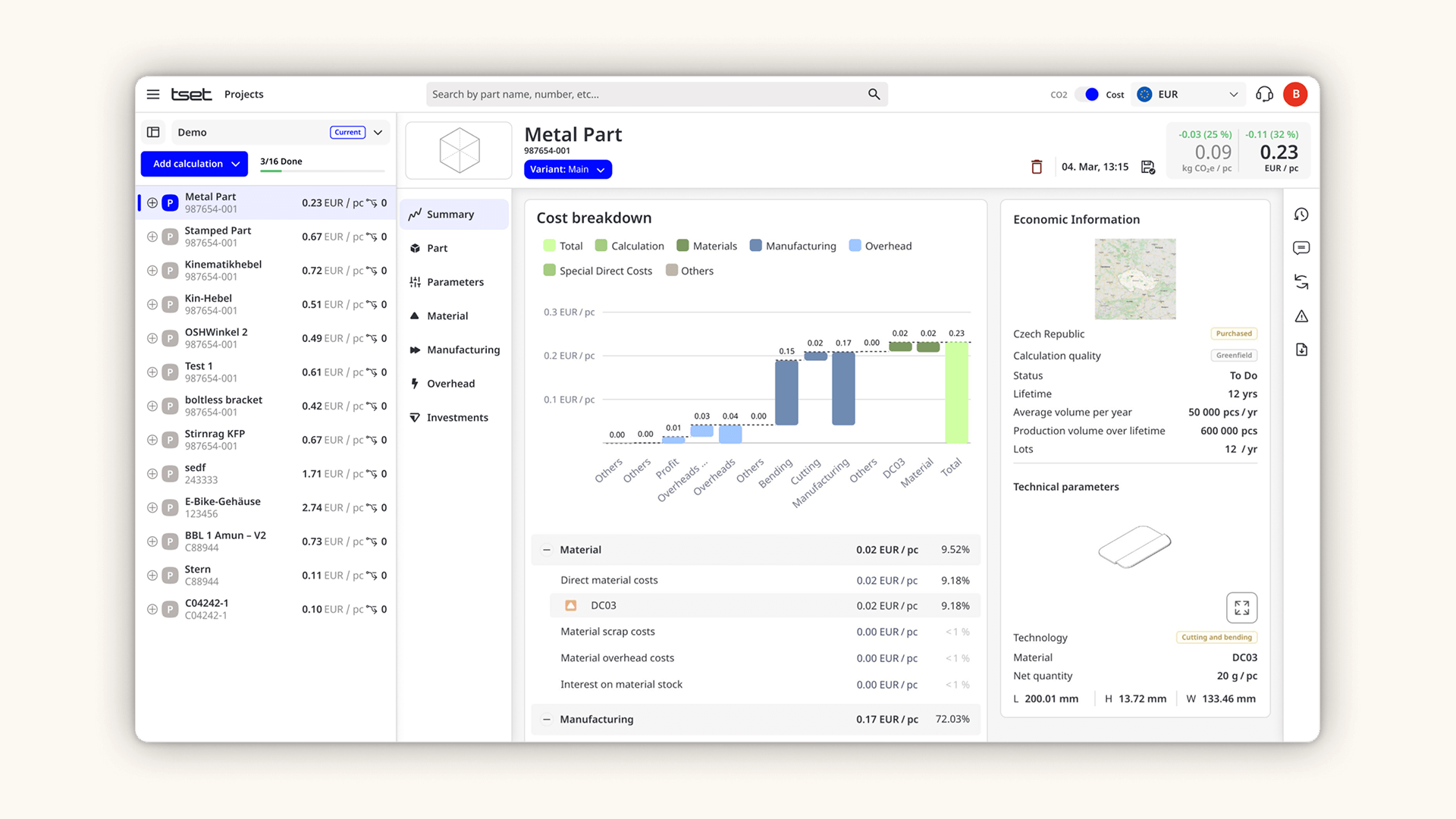

Tset offers a purpose-built product costing software solution that addresses these needs. As a cloud-based tool, it allows teams to access centralized cost data, simulate design and sourcing changes instantly, and compare internal costs with market benchmarks in a single environment.

Key features of Tset include:

-

Automated bottom-up cost estimation modules

-

Integration with ERP and PLM systems for seamless data flow

-

Support for Scope 3 upstream emissions tracking

-

Collaborative workspaces that align engineering, procurement, and business users

How Do Your Costs Compare?

In this hands-on webinar, we will show you how to identify hidden cost drivers, validate make-or-buy decisions, and optimize your production costs against market leaders.

1. What is product cost benchmarking?

Product cost benchmarking is the process of comparing the cost structure of a product with competitors, industry standards, or internal targets. It allows manufacturers to assess if their products are competitively priced and cost-efficient while identifying areas for improvement such as material usage, production processes, or design choices.

2. How does benchmarking influence product positioning?

Benchmarking helps companies align product features, design complexity, and pricing with market expectations. It reveals whether a product is under- or over-engineered compared to competitors, enabling smarter decisions around trade-offs, feature sets, and pricing strategies. This alignment improves how a product is positioned in the market.

3. When should a company perform product cost benchmarking?

Benchmarking is valuable throughout the product lifecycle, but especially during early development, sourcing, and portfolio review phases. The most strategic use cases include launching new products, entering competitive markets, revisiting legacy products, or validating supplier quotes during procurement.

4. What’s the difference between product cost benchmarking and should-cost analysis?

Should-cost analysis estimates what a product should cost based on materials, labor, and overhead. Product cost benchmarking, on the other hand, compares those costs to market references or competitor data. Together, they provide a more complete view for sourcing, pricing, and product design decisions.

5. Which departments benefit from product cost benchmarking?

While cost engineers may lead the process, benchmarking insights are valuable across product development, procurement, sales, and corporate strategy teams. It supports everything from technical feasibility and supplier negotiations to pricing strategy and product portfolio planning.

6. Why are spreadsheets or legacy tools not sufficient for benchmarking?

Traditional tools like Excel are prone to version control issues, lack data traceability, and cannot support real-time collaboration or scenario simulations. Modern product cost software enables faster, more accurate, and collaborative benchmarking that scales with product complexity and organizational needs.

Ready to Benchmark Smarter?

Uncover where your product stands—and where it can go. Talk to our team to see how Tset’s software helps you turn cost data into competitive advantage.