Imagine negotiating with a supplier, only to find that raw material prices have jumped overnight. Your carefully planned cost estimates are now obsolete, and your margins are shrinking. Sound familiar?

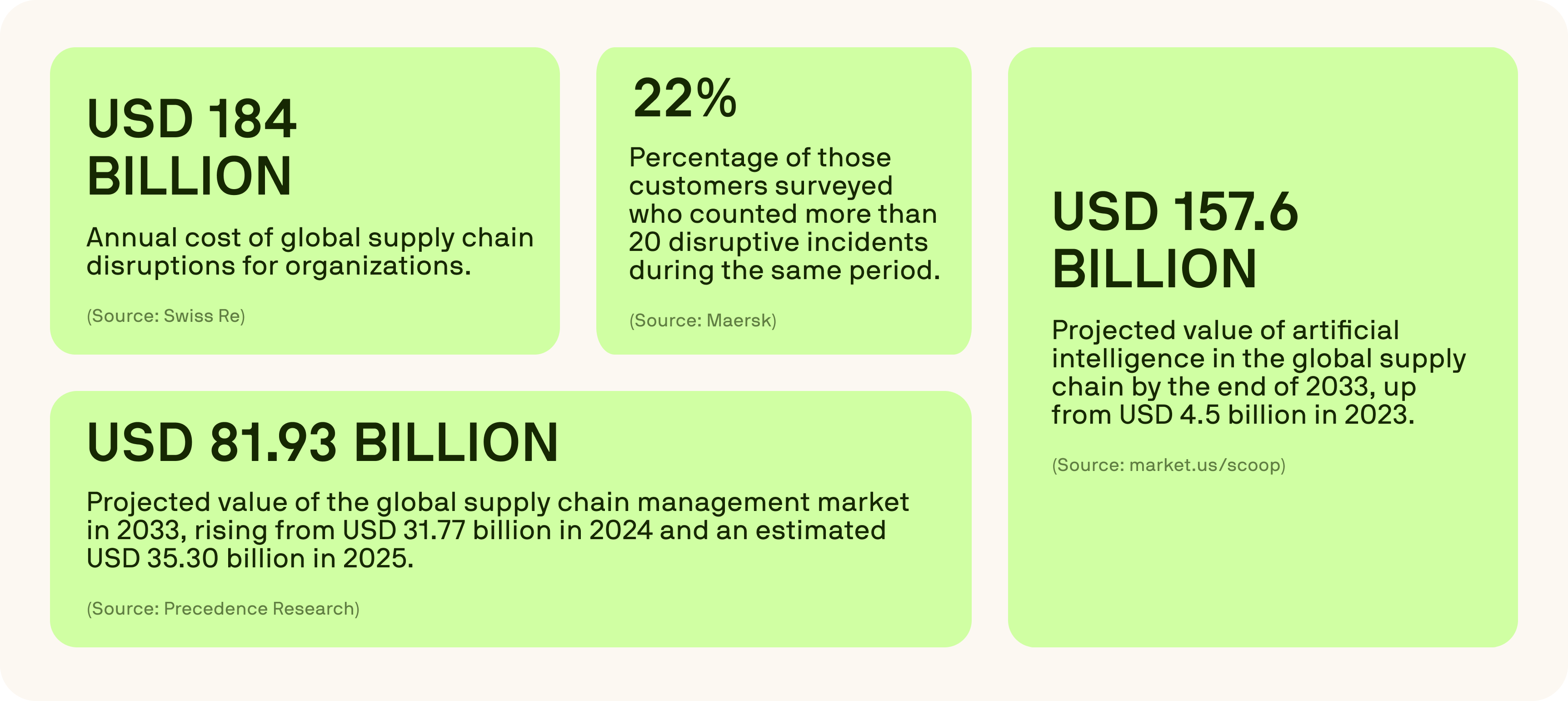

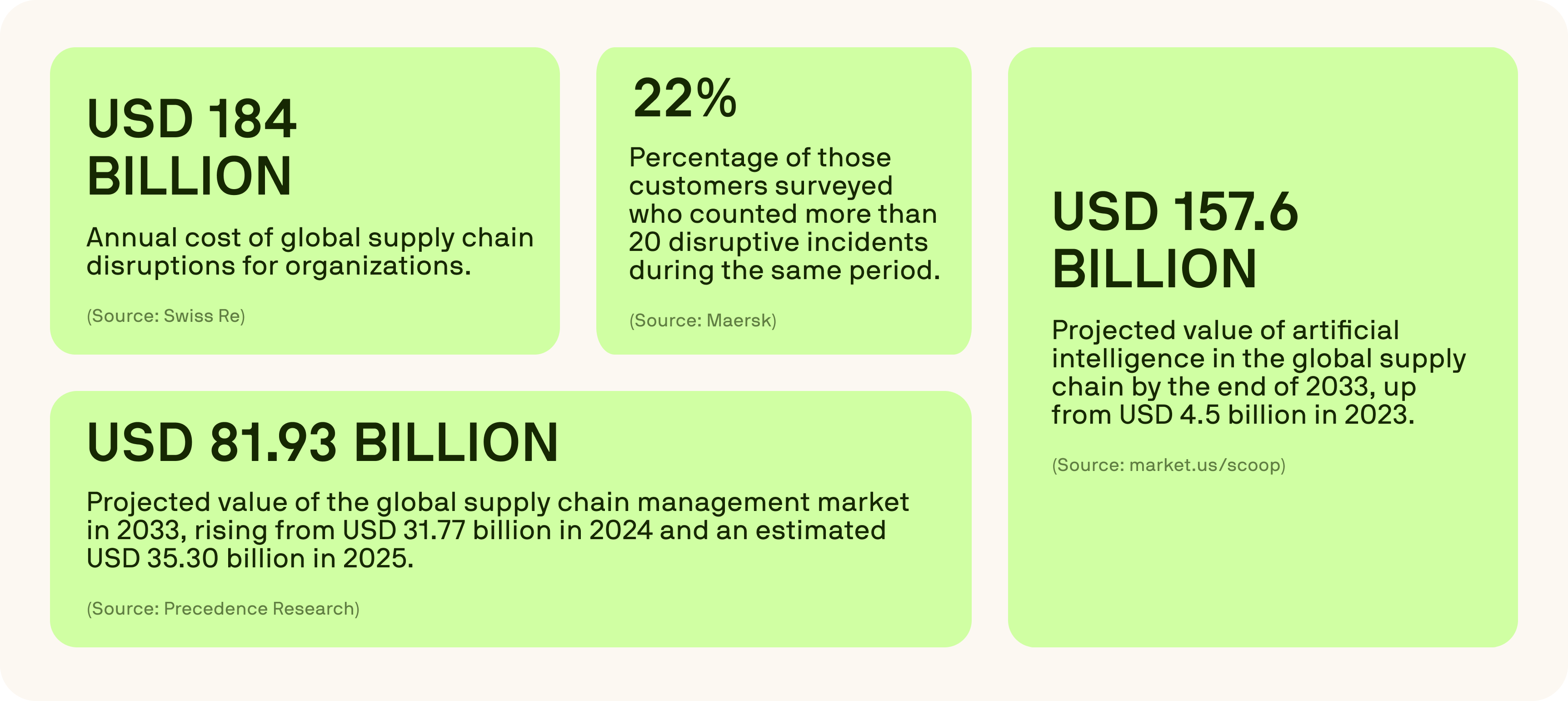

Supply chains are more volatile than ever, forcing cost engineers and procurement specialists to rethink supplier cost strategies. In the first half of 2024 alone, reported disruptions increased by 30% year-over-year, with factory fires, labor disputes, extreme weather events and cyberattacks among the top causes. These incidents cost organizations an estimated $184 billion annually, according to the 2025 J.S. Held Global Risk Report.

Despite these challenges, many cost engineering teams still rely on outdated cost estimation methods. A 2024 study found that procurement teams use only 5-10% of available technology, leading to inefficiencies and poor decision-making.

Using AI to Anticipate Supplier Price Shifts

For a long time, cost engineering and procurement teams have relied on historical data and spreadsheets to estimate supplier costs. But in today’s volatile market, that’s no longer enough.